Solution-Processed Two-Dimensional Materials for Scalable Production of Photodetector Arrays

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License(https://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Two-dimensional (2D) nanomaterials have demonstrated the potential to replace silicon and compound semiconductors that are conventionally used in photodetectors. These materials are ultrathin and have superior electrical and optoelectronic properties as well as mechanical flexibility. Consequently, they are particularly advantageous for fabricating high-performance photodetectors that can be used for wearable device applications and Internet of Things technology. Although prototype photodetectors based on single microflakes of 2D materials have demonstrated excellent photoresponsivity across the entire optical spectrum, their practical applications are limited due to the difficulties in scaling up the synthesis process while maintaining the optoelectronic performance. In this review, we discuss facile methods to mass-produce 2D material-based photodetectors based on the exfoliation of van der Waals crystals into nanosheet dispersions. We first introduce the liquid-phase exfoliation process, which has been widely investigated for the scalable fabrication of photodetectors. Solution processing techniques to assemble 2D nanosheets into thin films and the optoelectronic performance of the fabricated devices are also presented. We conclude by discussing the limitations associated with liquid-phase exfoliation and the recent advances made due to the development of the electrochemical exfoliation process with molecular intercalants.

Keywords:

Photodetector, Optoelectronics, Two-dimensional materials, Solution processing1. INTRODUCTION

Photodetectors are a class of optoelectronic devices that convert light into electrical signals. They are critical in various applications such as image sensing, telecommunications, and spectrophotometry [1-3]. Photodetectors typically consist of an active semiconducting channel that generates electrons and holes from incident photons with energies higher than the bandgap. These electrons and holes are then transported to the respective electrodes and collected as signals. Because each semiconductor exhibits an optimal spectral range of photodetection depending on its electronic band structure, multiple materials systems are developed to cover the whole electromagnetic spectrum [1-3]. Commercial visible photodetectors are mostly based on silicon because of their optoelectronic properties, processibility, and cost-effectiveness. In contrast, ultraviolet (UV), near-infrared (NIR), and infrared (IR) photodetectors are composed of epitaxially-grown compound semiconductor thin films, such as gallium nitride (GaN) and indium gallium arsenide (InGaAs) [2,3]. Although these conventional semiconductors are well established, their sensitivity still needs to be improved (photoresponsivity of conventional semiconductors is typically < 1 AW–1) [2-7]. Moreover, the applications of compound semiconductors are limited because of their high cost, incompatibility with the complementary metal-oxide semiconductor process, and the complexity of the thin-film growth process. This further motivates the development of alternative material systems [3].

Two-dimensional (2D) nanomaterials have received significant attention as promising candidates for high-performance photodetectors because of their unique electronic and optical properties [8-10]. In addition, their atomically thin structure and excellent mechanical flexibility makes them suitable for manufacturing flexible and wearable devices, which are challenging to realize using conventional semiconductors [8]. Since the development of prototype photodetectors based on graphene microflakes (produced via micromechanical exfoliation of graphite) [11,12], other 2D materials, such as transition metal dichalcogenides (TMDCs) and black phosphorus (BP), have been successfully used to develop photodetectors with a wide range of spectral responsivities [13-18]. Although the photodetectors fabricated using microflakes obtained from the micromechanical exfoliation of 2D materials exhibit excellent optoelectronic performance, the production yield of such microflakes is very low. In addition, the precise positioning of microflakes onto predefined areas is extremely time-consuming. Thus, this method is only suitable for fundamental research and cannot be used for practical applications, which require scalable and high-throughput methods for fabricating photodetector arrays. To this end, liquid-phase exfoliation (LPE) of bulk van der Waals crystals has been intensively investigated, as it is a facile and scalable method for producing 2D nanomaterials [19-21]. The resulting nanosheet dispersions can be assembled into thin films using facile solution processing techniques, thereby improving the scalability and throughput of the photodetector fabrication process [22,23]. However, one major drawback of the LPE process is that the generated nanosheets have a small lateral size (typically < 100 nm) and broad distribution in thickness [24-26]. Hence, the electrical and optoelectronic performance of the resulting thin film is poorer than the individual 2D nanosheets because of the high inter-sheet junction resistances [27]. To address this, electrochemical exfoliation processes that use molecular intercalants have been recently developed [28,29]. The resulting 2D nanosheets are characterized by large lateral sizes (from hundreds of nanometers to over a micron) and a narrow thickness distribution, thus enabling the formation of low-resistance conformal inter-sheet junctions with large overlap areas. Therefore, 2D nanosheets produced by electrochemically driven molecular intercalation and exfoliation are bringing about major advances in the fields of electronics and optoelectronics [28,30,31].

In this work, we review the recent advances in solution-processed 2D materials in the context of photodetectors. First, we present the spectral range in which various 2D materials exhibit optimal photoresponsivity and the corresponding photodetectors based on the microflakes generated by the micromechanical exfoliation of these 2D materials. Next, we discuss the LPE process for producing nanosheet dispersions of 2D materials, solution processing techniques for thin-film formation, and optoelectronic characteristics of the resulting photodetectors. Finally, we explore the recently developed electrochemical exfoliation process based on molecular intercalants and briefly discuss its advantages in achieving high-performance photodetectors.

2. Prototype Photodetectors based on 2D Microflakes

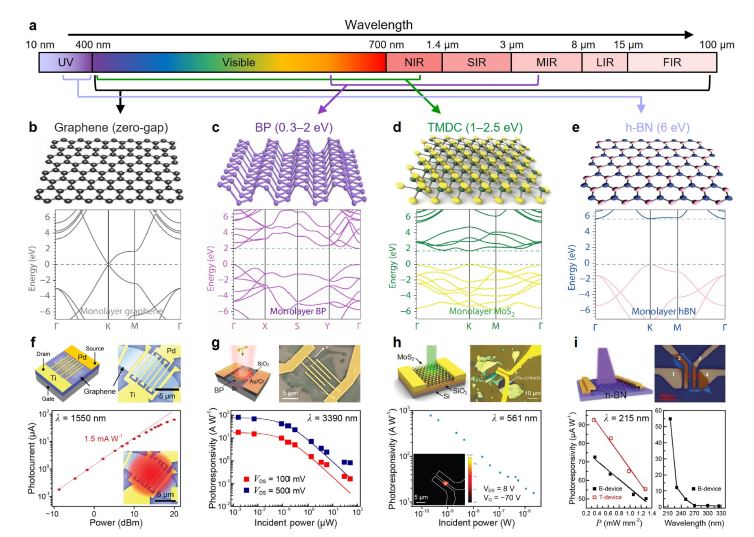

Fig. 1a shows the optical radiation portion of the electromagnetic spectrum, which includes the UV, visible, and IR wavelengths. Owing to the diverse electronic properties of 2D materials, 2D material-based photodetectors can operate over the entire optical radiation spectrum (Figs. 1b–e) [9, 10, 32]. Since its discovery in 2004 [33], graphene has been widely investigated for applications in broadband photodetectors because of its zero-band-gap electronic structure, which enables the absorption of light across a broad range of wavelengths, i.e., from visible to infrared (Fig. 1b) [11-13]. In addition, the exceptionally high charge carrier mobility of graphene is particularly promising for ultra-fast photodetector applications [11, 12]. Fig. 1f shows a representative photodetector composed of a micromechanically exfoliated graphene microflake with a field-effect transistor (FET) configuration [12, 13]. This device has been shown to exhibit a maximum photoresponsivity of 6.1 mA W–1 under an optical excitation of 1.55 μm and broad operational wavelength range (300 nm to over 6 μm) [12, 13]. Despite the superior electrical and optical properties of graphene, the performance of graphene photodetectors is limited because of the weak optical absorption (approximately 2.3%) and large dark current resulting from the zero band gap [34]. Consequently, other 2D materials, such as transition metal dichalcogenides (TMDCs) and black phosphorus (BP), have been investigated, especially for constructing photodetectors that can operate in the visible and NIR regimes [13-18]. In particular, 2D BP (or phosphorene) has a direct bandgap (0.3–2 eV) that depends on the number of layers and a high hole mobility (up to 1000 cm2 V–1s–1) [35], which further motivates its use in fabricating visible and NIR photodetectors (Fig. 1c). Photodetectors composed of micromechanically exfoliated BP microflakes have been demonstrated to exhibit a maximum photoresponsivity of approximately 102 A W–1 when illuminated with light of wavelength 3.39 μm (Fig. 1g) [16]. TMDCs have been widely used to construct visible photodetectors because their band gap ranges from 1 to 2.5 eV (Fig. 1d). In particular, photodetectors based on micromechanically exfoliated monolayer MoS2 with a back-gate FET configuration have been shown to achieve an exceptionally high photoresponsivity of 880 A W–1 at 532 nm (Fig. 1h) [15]. Although 2D materials have been actively used for fabricating visible and IR photodetectors, 2D material-based UV photodetectors have been relatively unexplored. To this end, hexagonal boron nitride (h-BN), which is commonly used as a high-quality insulator in van der Waals heterojunctions because of its wide band gap (up to 6 eV), has exhibited great promise in detecting UV light (Fig. 1e) [36,37]. Photodetectors based on micromechanically exfoliated h-BN microflakes have been demonstrated to sense deep UV (200–280 nm) and vacuum UV (100–200 nm) radiations with a photoresponsivity ranging from tens of μA W–1 to a few A W–1 (Fig. 1i) [36,37].

Spectral response of 2D material-based photodetectors. (a) Optical radiation portion of the electromagnetic spectrum (UV, visible, and IR). Atomic structures and representative electronic band structures of 2D materials: (b) graphene; (c) BP; (d) MoS2 (TMDC); and (e) h-BN. (b–e) Reproduced with permission from Ref. [32]; copyright 2020, Royal Society of Chemistry. Representative photodetectors based on 2D microflakes produced by the micromechanical exfoliation of: (f) graphene (reproduced with permission from Ref. [13]; copyright 2018, Elsevier); (g) BP (reproduced with permission from Ref. [16]; copyright 2016, American Chemical Society); (h) MoS2 (reproduced with permission from Ref. [8]; copyright 2017, Wiley-VCH); and (i) h-BN (reproduced with permission from Ref. [37]; copyright 2020, American Institute of Physics).

3. LPE FOR SCALABLE PRODUCTION OF PHOTODETECTOR ARRAYS

3.1 LPE of van der Waals crystals

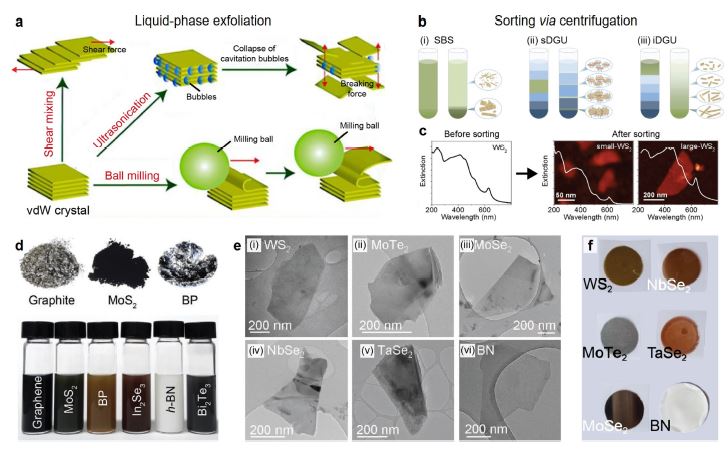

Although prototype photodetectors based on micromechanically exfoliated 2D materials have demonstrated promising optoelectronic performance at the microscale device level, the scalability and throughput of the fabrication process needs to be addressed to bridge the gap between fundamental research and practical applications. Among the various methods available for the scalable synthesis of 2D materials, LPE of van der Waals crystals is particularly advantageous because it does not require high temperature and vacuum processing conditions unlike chemical vapor deposition [19-21]. Fig. 2a presents the three different techniques used to perform LPE to produce nanosheet dispersions of 2D materials [22]. The most commonly adopted strategy is to immerse the crystal in a liquid medium and apply ultrasound waves using a probe sonicator. During the ultrasonication process, cavitation bubbles that form near the crystal collapse to generate shock waves and microjets, which can break the van der Waals forces between the layers of the 2D material [38]. Alternatively, van der Waals crystals can also be exfoliated by applying a shear force using a rotor-stator mixer or ball mill [39,40]. LPE of the 2D material leads to the formation of a polydispersed nanosheet dispersion with a broad distribution in lateral sizes and thicknesses [19]. Because the electronic and optical properties of the 2D material depend on the size and shape of the nanosheets, the nanosheet dispersion needs to be sorted via centrifugation (Fig. 2b) [19,20,41]. The simplest centrifugation-based sorting approach is sedimentation-based separation (SBS), which sorts the nanosheets based on their mass (Fig. 2b(i)) [41]. For a more precise sorting, sedimentation-based density gradient ultracentrifugation (sDGU) should be performed, where the density gradient of the medium is used to distinguish between nanosheets of different masses and lateral sizes (Fig. 2b(ii)). Lastly, isopycnic DGU (iDGU) sorts nanosheets according to their buoyant density, leading to the separation of the dispersion into multiple populations of similar thickness, and hence, similar electronic properties (Fig. 2b(iii)). Fig. 2c shows an example of centrifugation-based sorting, where WS2 nanosheets resulting from LPE are separated into two distinct populations of different lateral sizes. A major advantage of the LPE process is that it can be applied to a wide variety of van der Waals crystals, leading to nanosheet dispersions having diverse electronic properties (Figs. 2d and e). Several 2D materials have been successfully exfoliated from their bulk crystals using LPE, including graphene, BP, h-BN, TMDCs, metal monochalcogenides, and metal trichalcogenides [41,42]. Furthermore, the resulting nanosheets can be easily assembled into large-area thin films via network formation (Fig. 2f).

LPE for scalable production of 2D materials. (a) Different techniques for performing LPE (reproduced with permission from Ref. [22]; copyright 2018, Royal Society of Chemistry). (b) Nanosheet sorting by different centrifugation methods. (c) Nanosheet sorting into two different populations. (b, c) Reproduced with permission from Ref. [20]; copyright 2016, Wiley-VCH. (d) Nanosheet dispersions of different 2D materials (reproduced with permission from Ref. [41]; copyright 2018, Royal Society of Chemistry). (e) Morphology of nanosheets resulting from LPE of different 2D materials. (f) Thin films of 2D materials formed by nanosheet assembly. (e, f) Reproduced with permission from Ref. [42]; copyright 2011, Wiley-VCH.

3.2 Solution processing for nanosheet assembly

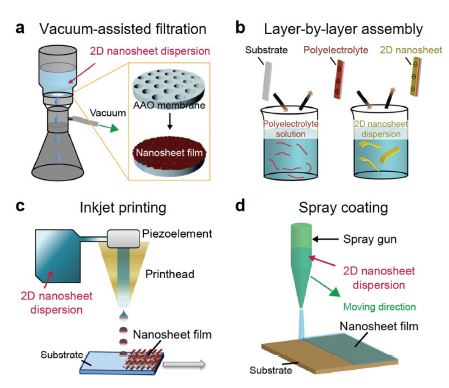

Nanosheet dispersions of 2D materials are compatible with various solution processing techniques, which are widely used for coating solution-based functional materials [20, 22] Vacuum-assisted filtration is the most common technique for generating thin films of 2D materials (Fig. 3a) [22]. During this process, the nanosheet dispersion is filtered through a porous membrane having pores of diameter less than 100 nm. The 2D nanosheets collect on top of the membrane to form a continuous network, while the solvent passes through the pores. In addition to the simplicity of the process, vacuum-assisted filtration offers design flexibility because the resulting films can be easily released from the membrane and transferred onto a desired substrate. Another method for generating thin films from nanosheet dispersions is layer-by-layer assembly (Fig. 3b) [22,43]. Exfoliated 2D nanosheets possess a certain charge, and hence, they can be deposited onto a target substrate by first immersing it into a polyelectrolyte solution having the opposite charge and then into the nanosheet dispersion. By alternating between the polyelectrolyte solution and nanosheet dispersion, the thickness of the nanosheet films can be controlled precisely. Because both vacuum-assisted filtration and layer-by-layer assembly produce 2D nanosheet films that cover the entire substrate area, additional patterning techniques (e.g., photolithography) are required to define channel regions for fabricating photodetectors. In contrast, inkjet printing enables the selective formation of nanosheet films on predefined patterned areas (Fig. 3c) [20,22]. Typically, piezoelectric elements are used to generate a pressure pulse on the ink reservoir, which ejects the 2D nanosheet dispersion in the form of ink droplets that are printed on the substrate to create a thin film. Another method to form 2D nanosheet films on a substrate in an area-selective manner is spray coating, during which the 2D nanosheet dispersion is expelled from a spray gun in the form of small aerosol droplets and deposited on the substrate to produce nanosheet films following solvent evaporation (Fig. 3d) [20,22]. The working principles of inkjet printing and spray coating have been discussed in detail in previous studies [22,41]. In addition to these four methods, other techniques such as Langmuir-Blodgett deposition [44], screen printing [45], and electrophoretic deposition [46] can also be used to form 2D nanosheet films over large areas.

3.3 Optoelectronic performance of LPE-processed 2D material-based photodetectors

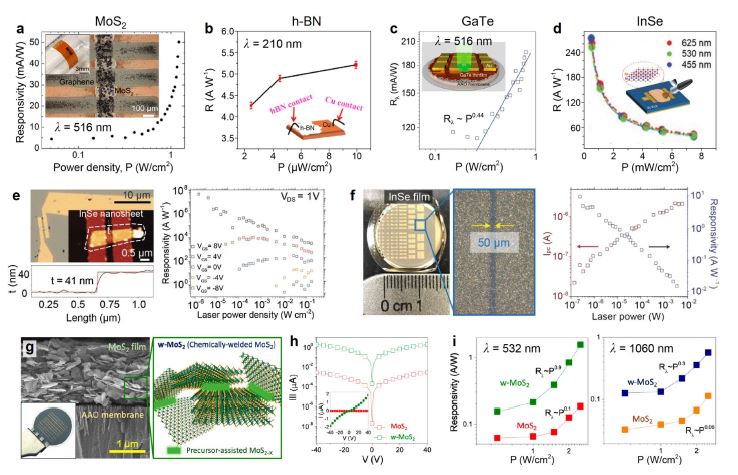

Because of the universality of the LPE and solution-phase deposition methods, a wide variety of 2D materials have been successfully processed into large-scale photodetector arrays (Fig. 4). Figs. 4a–d show representative photodetectors composed of different 2D materials with their active channel layers created using different solution processing techniques. For example, in the MoS2 photodetector shown in Fig. 4a, MoS2 and graphene nanosheets were generated using ultrasonication-assisted LPE, which were then inkjet-printed onto a polyimide substrate to form the semiconducting channels and electrodes, respectively [26]. The resulting flexible photodetector achieved a maximum photoresponsivity of 50 mA W–1 when illuminated with a laser of wavelength 516 nm and exhibited mechanical stability during repeated bending cycles. Drop casting can also be used to fabricate photodetectors in which precise patterning is not necessary. Fig. 4b shows a deep UV photodetector based on h-BN nanosheet films drop-casted onto a copper foil [47]. A Schottky barrier forms between the h-BN film and copper substrate, which leads to an exceptionally high photoresponsivity (approximately 5 A W–1) for deep UV light (210 nm). In addition to graphene, TMDCs, and h-BN, emerging 2D materials such as metal monochalcogenides have been successfully used to fabricate photodetectors using LPE and solution processing. For example, large-area photodetectors based on liquid-phase exfoliated gallium telluride (GaTe) [48] and indium selenide (InSe) [49] have been successfully realized using vacuum-assisted filtration and spray coating (Figs. 4c and d).

Photodetectors based on liquid-phase exfoliated 2D nanomaterials. Photodetectors fabricated using nanosheet films composed of: (a) MoS2 (reproduced with permission from Ref. [26]; copyright 2019, American Chemical Society); (b) h-BN (reproduced with permission from Ref. [47]; copyright 2021, American Chemical Society); (c) GaTe (reproduced with permission from Ref. [48]; copyright 2018, American Chemical Society); and (d) InSe (reproduced with permission from Ref. [49]; copyright 2020, Wiley-VCH). Optoelectronic performance of liquid-phase exfoliated InSe photodetector based on a: (e) single nanosheet and (f) thin film formed by a network of nanosheets. (e, f) Reproduced with permission from Ref. [50]; copyright 2018, Wiley-VCH. (g) Chemical welding of MoS2 nanosheet film. Effect of chemical welding on MoS2 nanosheet film: (h) electrical properties and (i) photoresponsivity. (g–i) Reproduced with permission from Ref. [52]; copyright 2021, American Chemical Society.

Although working photodetectors based on LPE-processed 2D nanosheet films have been successfully developed, their optoelectronic performance is considerably poorer than that of photodetectors based on single microflakes produced by micromechanical exfoliation. The discrepancy between the photoresponsivity of individual 2D flakes and that of a network of 2D thin films is clearly demonstrated by liquid-phase exfoliated InSe nanosheets (Figs. 4e and f) [50]. Fig. 4e shows the photoresponsivity of an LPE-processed single InSe nanosheet under illumination by a laser of wavelength 516 nm. This nanosheet was exfoliated using a surfactant-free, deoxygenated, co-solvent mixture to prevent chemical degradation. To fabricate a photodetector, the InSe nanosheet was transferred onto a heavily doped silicon substrate that was coated with a 20-nm thick Al2O3 gate dielectric film, followed by electrode deposition. Owing to the surfactant- and oxygen-free exfoliation process, the InSe nanosheet achieved a field-effect mobility (approximately 19 cm2 V-1s-1) and current on/off ratio (approximately 106) comparable to that of micromechanically exfoliated few-layer InSe flakes [51]. Interestingly, the single-nanosheet InSe photodetector exhibited an exceptionally high photoresponsivity of 5 × 107 A W–1 for an optical power density of approximately 10–6 W cm–2 as well as distinct gate tunability in the photoresponse behavior. When the InSe nanosheets were assembled into a thin film using vacuum-assisted filtration (for scalable device fabrication), the maximum photoresponsivity of the film decreased by more than 6 orders of magnitude (Fig. 4f). Such a dramatic reduction in the photoresponsivity is mainly due to a decrease in the charge carrier mobility, which in turn is caused by the nanosheet assembly into thin films. This is because LPE-processed nanosheets in a network are typically connected by numerous edge-to-edge junctions with poor inter-sheet overlap; consequently, significant junction resistances develop to impede the transport of photogenerated charge carriers [27]. Furthermore, the nanosheets are not closely aligned along the in-plane direction because of their small lateral size and large dispersion in thickness, which further decreases the charge carrier mobility compared to that of single nanosheets with perfect in-plane alignment [27].

To improve charge transport across the inter-sheet junctions, a precursor-assisted chemical welding process has been recently proposed [52]. For example, application of an ammonium tetrathiomolybdate ((NH4)2MoS4) precursor solution to the MoS2 nanosheet film followed by thermal annealing produces substoichiometric MoS2-x at the inter-sheet junctions (Fig. 4g). This increases the electrical conductivity of the MoS2 nanosheet by more than 2 orders of magnitude (Fig. 4h) compared to that of the as-prepared nanosheet, which in turn results in an enhanced photoresponsivity (Fig. 4i). Moreover, the additional defect states corresponding to the MoS2-x at the welded interface enables photodetection at NIR wavelengths, which is otherwise not possible due to the intrinsic band structure of MoS2.

4. ELECTROCHEMICAL EXFOLIATION FOR HIGH-PERFORMANCE DEVICES

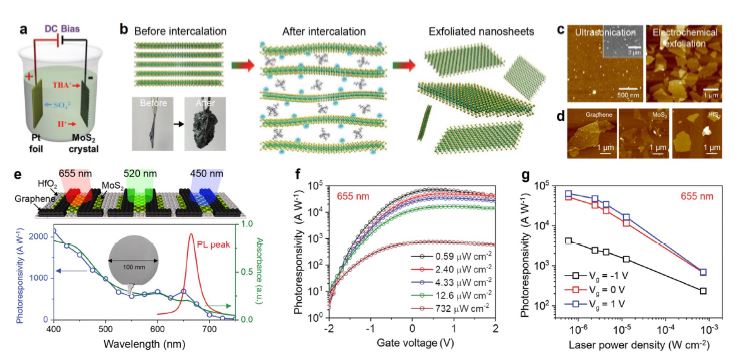

Although chemical welding has shown promise in enhancing the optoelectronic performance of LPE-processed 2D nanosheet films, there are two main drawbacks that hinder the practical use of this process for generic 2D nanomaterials: (1) different precursor solutions are required for different 2D materials and (2) the photoresponsivity is still significantly lower than that of micromechanically exfoliated single flakes. To improve charge transport in solution-processed 2D nanosheet films, electrochemical exfoliation using molecular intercalants has been recently proposed [28,29]. In this process, quaternary ammonium molecular ions such as tetraheptylammonium (THA+) and tetrabutylammonium (TBA+) ions are intercalated into a bulk van der Waals crystal loaded at the cathode of an electrochemical cell operating under a DC voltage. This effectively expands the interlayer spacing and breaks the van der Waals bonds between the nanosheet layers (Figs. 5a and b). Following a mild sonication, 2D nanosheets with large lateral sizes (from several hundreds of nanometers to over a micron) are produced with a narrow thickness distribution. Fig. 5c compares the morphologies of the MoS2 nanosheets produced via ultrasonication-assisted LPE and electrochemical exfoliation [53]. The electrochemically exfoliated MoS2 nanosheets are characterized by much larger lateral sizes and a narrower thickness distribution, thus enabling the formation of conformal inter-sheet junctions with large overlapping areas within the nanosheet network [27]. Consequently, the resulting 2D nanosheet film exhibits superior electrical properties owing to the significantly reduced inter-sheet junction resistances and superior in-plane alignment of the nanosheets [31]. Notably, this method can be applied to various 2D materials to yield high-quality nanosheet dispersions. Subsequently, these dispersions can be assembled into continuous thin films via spin coating, which has been challenging to achieve with LPE-processed 2D nanosheets (Fig. 5d) [31].

Electrochemically-driven molecular intercalation for fabricating high-performance 2D photodetectors. (a) Electrochemical cell for the intercalation process. (b) Schematic illustration of the molecular intercalation and exfoliation processes. (a, b) Reproduced with permission from Ref. [29]; copyright 2019, Wiley-VCH. (c) Difference in morphologies between MoS2 nanosheets produced via ultrasonication-assisted LPE and electrochemical exfoliation (reproduced with permission from Ref. [53]; copyright 2021, Wiley-VCH). (d) Electrochemical exfoliation of different 2D materials. (e) Wafer-scale array of photodetectors based on electrochemically exfoliated MoS2 (semiconducting channel), HfO2 (gate dielectric), and graphene (electrodes) nanosheet films and the corresponding spectral photoresponsivities. Photoresponsivity under 655-nm laser illumination as a function of: (f) gate bias and (g) laser power density. (d–g) Reproduced with permission from Ref. [31]; copyright 2022, Wiley-VCH.

Wafer-scale phototransistor arrays have been constructed by processing electrochemically exfoliated graphene, MoS2, and HfO2 nanosheets into electrodes, semiconducting channels, and gate dielectrics, respectively (Fig. 5e) [31]. The resulting device exhibited excellent electrical performance with a field-effect mobility of 8.3 cm2 V–1s–1 and a current on/off ratio of 1.6 × 106, and it could be operated with low gate biases because of the high areal capacitance of the HfO2 nanosheet dielectric. Furthermore, broadband photoresponsivity was realized across the entire visible spectrum, which could be tuned by varying the gate voltage (Figs. 5e–g). In particular, the maximum photoresponsivity achieved was greater than 104 A W–1 under laser excitation at 655 nm, which is much higher than that of previously reported photodetectors based on solution-processed TMDC channels. Furthermore, the proposed method is suitable for low-power optoelectronics because the resulting photodetectors can fully operate under drain and gate voltages of 1 V and 0.1 V, respectively.

5. CONCLUSIONS

In this review, we discussed the progress made in the scalable production of photodetectors fabricated using solution-based exfoliation of 2D van der Waals crystals. Because the exfoliation process can be universally applied to a wide range of 2D materials, photodetectors with diverse spectral responses can be realized for a single class of materials. With the advent of electrochemical exfoliation that can produce structurally homogeneous 2D nanosheets with large lateral sizes, solution-processed 2D nanosheet thin films are now beginning to bring about breakthroughs for the scalable manufacturing of high-performance photodetectors. Furthermore, the scalability of the nanosheet thin-film production process enables the fabrication of large-area van der Waals heterostructures, which offers a wide range of tunability in the electronic band structure for engineering the optoelectronic performance of wafer-scale photodetector arrays. With further refinement in the electrochemical exfoliation process as well as other chemical treatment strategies, we expect that solution-processed 2D materials will become highly compelling for next-generation photodetectors for practical applications.

Acknowledgments

This study was supported by the National Research Foundation of Korea (NRF) funded by the Korean Government (MSIT; grant no. 2020R1C1C1009381) and the Korea Basic Science Institute (KBSI) National Research Facilities and Equipment Center (NFEC) grant funded by the Korean Government (Ministry of Education) (2019R1A6C1010031).

REFERENCES

-

J. Liu, S. Cristoloveanu, and J. Wan, “A Review on the Recent Progress of Silicon-on-Insulator-Based Photodetectors”, Phys. Status Solidi A, Vol. 218, No. 14, p. 2000751, 2021.

[https://doi.org/10.1002/pssa.202000751]

-

W. Feng, J. B. Wu, X. Li, W. Zheng, X. Zhou, K. Xiao, W. Cao, B. Yang, J. C. Idrobo, L. Basile, W. Tian, P. Tan, and P. Hu, “Ultrahigh Photo-Responsivity and Detectivity in Multilayer InSe Nanosheets Phototransistors with Broadband Response”, J. Mater. Chem. C, Vol. 3, No. 27, pp. 7022-7028, 2015.

[https://doi.org/10.1039/C5TC01208B]

-

N. Huo and G. Konstantatos, “Recent Progress and Future Prospects of 2D-Based Photodetectors”, Adv. Mater., Vol. 30, No. 51, p. 1801164, 2018.

[https://doi.org/10.1002/adma.201801164]

-

J. Jang, P. Choi, H. K. Lyu, and J. K. Shin, “Photocurrent Characteristics of Gate/Body-Tied MOSFET-Type Photodetector with High Sensitivity”, J. Sens. Sci. Technol., Vol. 31, No. 3, pp. 1-5, 2022.

[https://doi.org/10.46670/JSST.2022.31.1.1]

-

H. B. Lee and S. H. Hahm, “A highly integrable p-GaN MSM photodetector with GaN n-channel MISFET for UV image sensor system”, J. Sens. Sci. Technol., Vol. 17, No. 5, pp. 346–349, 2008.

[https://doi.org/10.5369/JSST.2008.17.5.346]

-

C. J. Lee and H. Park, “Surface Passivation Method for GaN UV Photodetectors Using Oxygen Annealing Treatment”, J. Sens. Sci. Technol., Vol. 25, No. 4, pp. 252–256, 2016.

[https://doi.org/10.5369/JSST.2016.25.4.252]

- J. Y. Cho, J. S. Kim, S. H. Son, J. H. Lee, and S. Y. Choi, “Fabrication and Characteristics of Infrared Photodiode Using Insb Wafer with p-i-n Structure”, J. Sens. Sci. Technol., Vol. 8, No. 3, pp. 239-246, 1999.

-

C. Xie, C. Mak, X. Tao, and F. Yan, “Photodetectors Based on Two-Dimensional Layered Materials Beyond Graphene”, Adv. Funct. Mater., Vol. 27, No. 19, p. 1603886, 2017.

[https://doi.org/10.1002/adfm.201603886]

-

Q. Qiu and Z. Huang, “Photodetectors of 2D Materials from Ultraviolet to Terahertz Waves”, Adv. Mater., Vol. 33, No. 15, p. 2008126, 2021.

[https://doi.org/10.1002/adma.202008126]

-

T. Tan, X. Jiang, C. Wang, B. Yao, and H. Zhang, “2D Material Optoelectronics for Information Functional Device Applications: Status and Challenges”, Adv. Sci., Vol. 7, No. 11, p. 2000058, 2020.

[https://doi.org/10.1002/advs.202000058]

-

F. Xia, T. Mueller, Y.-m. Lin, A. Valdes-Garcia, and P. Avouris, “Ultrafast Graphene Photodetector”, Nat. Nanotechnol., Vol. 4, No. 12, pp. 839-843, 2009.

[https://doi.org/10.1038/nnano.2009.292]

-

T. Mueller, F. Xia, and P. Avouris, “Graphene Photodetectors for High-Speed Optical Communications”, Nat. Photonics, Vol. 4, No. 5, pp. 297-301, 2010.

[https://doi.org/10.1038/nphoton.2010.40]

-

G. Wang, Y. Zhang, C. You, B. Liu, Y. Yang, H. Li, A. Cui, D. Liu, and H. Yan, “Two Dimensional Materials Based Photodetectors”, Infrared Phys. Technol., Vol. 88, No. pp. 149-173, 2018.

[https://doi.org/10.1016/j.infrared.2017.11.009]

-

Z. Yin, H. Li, H. Li, L. Jiang, Y. Shi, Y. Sun, G. Lu, Q. Zhang, X. Chen, and H. Zhang, “Single-Layer MoS2 Phototransistors”, ACS Nano, Vol. 6, No. 1, pp. 74-80, 2012.

[https://doi.org/10.1021/nn2024557]

-

O. Lopez-Sanchez, D. Lembke, M. Kayci, A. Radenovic, and A. Kis, “Ultrasensitive Photodetectors Based on Monolayer MoS2”, Nat. Nanotechnol., Vol. 8, No. 7, pp. 497-501, 2013.

[https://doi.org/10.1038/nnano.2013.100]

-

Q. Guo, A. Pospischil, M. Bhuiyan, H. Jiang, H. Tian, D. Farmer, B. Deng, C. Li, S. J. Han, H. Wang, Q. Xia, T. P. Ma, T. Mueller, and F. Xia, “Black Phosphorus Mid-Infrared Photodetectors with High Gain”, Nano Lett., Vol. 16, No. 7, pp. 4648-4655, 2016.

[https://doi.org/10.1021/acs.nanolett.6b01977]

-

M. Huang, M. Wang, C. Chen, Z. Ma, X. Li, J. Han, and Y. Wu, “Broadband Black-Phosphorus Photodetectors with High Responsivity”, Adv. Mater., Vol. 28, No. 18, pp. 3481-3485, 2016.

[https://doi.org/10.1002/adma.201506352]

-

X. Chen, X. Lu, B. Deng, O. Sinai, Y. Shao, C. Li, S. Yuan, V. Tran, K. Watanabe, T. Taniguchi, D. Naveh, L. Yang, and F. Xia, “Widely Tunable Black Phosphorus Mid-Infrared Photodetector”, Nat. Commun., Vol. 8, No. 1, p. 1672, 2017.

[https://doi.org/10.1038/s41467-017-01978-3]

-

J. Kang, V. K. Sangwan, J. D. Wood, and M. C. Hersam, “Solution-Based Processing of Monodisperse Two-Dimensional Nanomaterials”, Acc. Chem. Res., Vol. 50, No. 4, pp. 943-951, 2017.

[https://doi.org/10.1021/acs.accounts.6b00643]

-

F. Bonaccorso, A. Bartolotta, J. N. Coleman, and C. Backes, “2D-Crystal-Based Functional Inks”, Adv. Mater., Vol. 28, No. 29, pp. 6136-6166, 2016.

[https://doi.org/10.1002/adma.201506410]

-

X. Gao, G. Bian, and J. Zhu, “Electronics from Solution-Processed 2D Semiconductors”, J. Mater. Chem. C, Vol. 7, No. 41, pp. 12835-12861, 2019.

[https://doi.org/10.1039/C9TC03935J]

-

X. Cai, Y. Luo, B. Liu, and H. M. Cheng, “Preparation of 2D Material Dispersions and Their Applications”, Chem. Soc. Rev., Vol. 47, No. 16, pp. 6224-6266, 2018.

[https://doi.org/10.1039/C8CS00254A]

-

F. I. Alzakia and S. C. Tan, “Liquid-Exfoliated 2D Materials for Optoelectronic Applications”, Adv. Sci., Vol. 8, No. 11, p. 2003864, 2021.

[https://doi.org/10.1002/advs.202003864]

-

E. B. Secor, P. L. Prabhumirashi, K. Puntambekar, M. L. Geier, and M. C. Hersam, “Inkjet Printing of High Conductivity, Flexible Graphene Patterns”, J. Phys. Chem. Lett., Vol. 4, No. 8, pp. 1347-1351, 2013.

[https://doi.org/10.1021/jz400644c]

-

J. Li, M. M. Naiini, S. Vaziri, M. C. Lemme, and M. Östling, “Inkjet Printing of MoS2”, Adv. Funct. Mater., Vol. 24, No. 41, pp. 6524-6531, 2014.

[https://doi.org/10.1002/adfm.201400984]

-

J. W. T. Seo, J. Zhu, V. K. Sangwan, E. B. Secor, S. G. Wallace, and M. C. Hersam, “Fully Inkjet-Printed, Mechanically Flexible MoS2 Nanosheet Photodetectors”, ACS Appl. Mater. Interfaces, Vol. 11, No. 6, pp. 5675-5681, 2019.

[https://doi.org/10.1021/acsami.8b19817]

-

A. G. Kelly, D. O’Suilleabhain, C. Gabbett, and J. N. Coleman, “The Electrical Conductivity of Solution-Processed Nanosheet Networks”, Nat. Rev. Mater., Vol. 7, No. 3, pp. 217-234, 2022.

[https://doi.org/10.1038/s41578-021-00386-w]

-

Z. Lin, Y. Liu, U. Halim, M. Ding, Y. Liu, Y. Wang, C. Jia, P. Chen, X. Duan, C. Wang, F. Song, M. Li, C. Wan, Y. Huang, and X. Duan, “Solution-Processable 2D Semiconductors for High-Performance Large-Area Electronics”, Nature, Vol. 562, No. 7726, pp. 254-258, 2018.

[https://doi.org/10.1038/s41586-018-0574-4]

-

P. Zhang, S. Yang, R. Pineda-Gómez, B. Ibarlucea, J. Ma, M. R. Lohe, T. F. Akbar, L. Baraban, G. Cuniberti, and X. Feng, “Electrochemically Exfoliated High-Quality 2H-MoS2 for Multiflake Thin Film Flexible Biosensors”, Small, Vol. 15, No. 23, p. 1901265, 2019.

[https://doi.org/10.1002/smll.201901265]

-

Z. Lin, Y. Huang, and X. Duan, “Van der Waals Thin-Film Electronics”, Nat. Electron., Vol. 2, No. 9, pp. 378-388, 2019.

[https://doi.org/10.1038/s41928-019-0301-7]

-

J. Kim, D. Rhee, O. Song, M. Kim, Y. H. Kwon, D. U. Lim, I. S. Kim, V. Mazánek, L. Valdman, Z. Sofer, J. H. Cho, and J. Kang, “All-Solution-Processed Van der Waals Heterostructures for Wafer-Scale Electronics”, Adv. Mater., Vol. 34, No. 12, p. 2106110, 2022.

[https://doi.org/10.1002/adma.202106110]

-

H. S. Nalwa, “A Review of Molybdenum Disulfide (MoS2) Based Photodetectors: From Ultra-Broadband, Self-Powered to Flexible Devices”, RSC Adv., Vol. 10, No. 51, pp. 30529-30602, 2020.

[https://doi.org/10.1039/D0RA03183F]

-

K. S. Novoselov, A. K. Geim, S. V. Morozov, D. Jiang, Y. Zhang, S. V. Dubonos, I. V. Grigorieva, and A. A. Firsov, “Electric Field Effect in Atomically Thin Carbon Films”, Science, Vol. 306, No. 5696, pp. 666-669, 2004.

[https://doi.org/10.1126/science.1102896]

-

F. Bonaccorso, Z. Sun, T. Hasan, and A. C. Ferrari, “Graphene Photonics and Optoelectronics”, Nat. Photonics, Vol. 4, No. 9, pp. 611-622, 2010.

[https://doi.org/10.1038/nphoton.2010.186]

-

L. Li, Y. Yu, G. J. Ye, Q. Ge, X. Ou, H. Wu, D. Feng, X. H. Chen, and Y. Zhang, “Black Phosphorus Field-Effect Transistors”, Nat. Nanotechnol., Vol. 9, No. 5, pp. 372-377, 2014.

[https://doi.org/10.1038/nnano.2014.35]

-

W. Zheng, R. Lin, Z. Zhang, and F. Huang, “Vacuum-Ultraviolet Photodetection in Few-Layered h-BN”, ACS Appl. Mater. Interfaces, Vol. 10, No. 32, pp. 27116-27123, 2018.

[https://doi.org/10.1021/acsami.8b07189]

-

N. Zhang, Y. Song, K. Zhou, and W. Wang, “Enhanced Performance of Solar-Blind Photodetector of Hexagonal Boron Nitride with Bottom-Contact Electrodes”, AIP. Adv., Vol. 10, No. 8, p. 085013, 2020.

[https://doi.org/10.1063/5.0010182]

-

M. Telkhozhayeva, E. Teblum, R. Konar, O. Girshevitz, I. Perelshtein, H. Aviv, Y. R. Tischler, and G. D. Nessim, “Higher Ultrasonic Frequency Liquid Phase Exfoliation Leads to Larger and Monolayer to Few-Layer Flakes of 2D Layered Materials”, Langmuir, Vol. 37, No. 15, pp. 4504-4514, 2021.

[https://doi.org/10.1021/acs.langmuir.0c03668]

-

K. R. Paton, E. Varrla, C. Backes, R. J. Smith, U. Khan, A. O’Neill, C. Boland, M. Lotya, O. M. Istrate, P. King, T. Higgins, S. Barwich, P. May, P. Puczkarski, I. Ahmed, M. Moebius, H. Pettersson, E. Long, J. Coelho, S. E. O’Brien, E. K. McGuire, B. M. Sanchez, G. S. Duesberg, N. McEvoy, T. J. Pennycook, C. Downing, A. Crossley, V. Nicolosi, and J. N. Coleman, “Scalable Production of Large Quantities of Defect-Free Few-Layer Graphene by Shear Exfoliation in Liquids”, Nat. Mater., Vol. 13, No. 6, pp. 624-630, 2014.

[https://doi.org/10.1038/nmat3944]

-

W. Zhao, M. Fang, F. Wu, H. Wu, L. Wang, and G. Chen, “Preparation of Graphene by Exfoliation of Graphite Using Wet Ball Milling”, J. Mater. Chem., Vol. 20, No. 28, pp. 5817-5819, 2010.

[https://doi.org/10.1039/c0jm01354d]

-

G. Hu, J. Kang, L. W. T. Ng, X. Zhu, R. C. T. Howe, C. G. Jones, M. C. Hersam, and T. Hasan, “Functional Inks and Printing of Two-Dimensional Materials”, Chem. Soc. Rev., Vol. 47, No. 9, pp. 3265-3300, 2018.

[https://doi.org/10.1039/C8CS00084K]

-

R. J. Smith, P. J. King, M. Lotya, C. Wirtz, U. Khan, S. De, A. O'Neill, G. S. Duesberg, J. C. Grunlan, G. Moriarty, J. Chen, J. Wang, A. I. Minett, V. Nicolosi, and J. N. Coleman, “Large-Scale Exfoliation of Inorganic Layered Compounds in Aqueous Surfactant Solutions”, Adv. Mater., Vol. 23, No. 34, pp. 3944-3948, 2011.

[https://doi.org/10.1002/adma.201102584]

-

J. Zhu, J. Kang, J. Kang, D. Jariwala, J. D. Wood, J. W. T. Seo, K. S. Chen, T. J. Marks, and M. C. Hersam, “Solution-Processed Dielectrics Based on Thickness-Sorted Two-Dimensional Hexagonal Boron Nitride Nanosheets”, Nano Lett., Vol. 15, No. 10, pp. 7029-7036, 2015.

[https://doi.org/10.1021/acs.nanolett.5b03075]

-

L. Xu, A. R. Tetreault, H. H. Khaligh, I. A. Goldthorpe, S. D. Wettig, and M. A. Pope, “Continuous Langmuir–Blodgett Deposition and Transfer by Controlled Edge-to-Edge Assembly of Floating 2D Materials”, Langmuir, Vol. 35, No. 1, pp. 51-59, 2019.

[https://doi.org/10.1021/acs.langmuir.8b03173]

-

P. He, J. Cao, H. Ding, C. Liu, J. Neilson, Z. Li, I. A. Kinloch, and B. Derby, “Screen-Printing of a Highly Conductive Graphene Ink for Flexible Printed Electronics”, ACS Appl. Mater. Interfaces, Vol. 11, No. 35, pp. 32225-32234, 2019.

[https://doi.org/10.1021/acsami.9b04589]

-

A. Chavez-Valdez, M. S. P. Shaffer, and A. R. Boccaccini, “Applications of Graphene Electrophoretic Deposition. A Review”, J. Phys. Chem. B, Vol. 117, No. 6, pp. 1502-1515, 2013.

[https://doi.org/10.1021/jp3064917]

-

S. Veeralingam, L. Durai, P. Yadav, and S. Badhulika, “Record-High Responsivity and Detectivity of a Flexible Deep-Ultraviolet Photodetector Based on Solid State-Assisted Synthesized hBN Nanosheets”, ACS Appl. Electron. Mater., Vol. 3, No. 3, pp. 1162-1169, 2021.

[https://doi.org/10.1021/acsaelm.0c01021]

-

J. Kang, V. K. Sangwan, H.-S. Lee, X. Liu, and M. C. Hersam, “Solution-Processed Layered Gallium Telluride Thin-Film Photodetectors”, ACS Photonics, Vol. 5, No. 10, pp. 3996-4002, 2018.

[https://doi.org/10.1021/acsphotonics.8b01066]

-

N. Curreli, M. Serri, D. Spirito, E. Lago, E. Petroni, B. Martín-García, A. Politano, B. Gurbülak, S. Duman, R. Krahne, V. Pellegrini, and F. Bonaccorso, “Liquid Phase Exfoliated Indium Selenide Based Highly Sensitive Photodetectors”, Adv. Funct. Mater., Vol. 30, No. 13, p. 1908427, 2020.

[https://doi.org/10.1002/adfm.201908427]

-

J. Kang, S. A. Wells, V. K. Sangwan, D. Lam, X. Liu, J. Luxa, Z. Sofer, and M. C. Hersam, “Solution-Based Processing of Optoelectronically Active Indium Selenide”, Adv. Mater., Vol. 30, No. 38, p. 1802990, 2018.

[https://doi.org/10.1002/adma.201802990]

-

S. Sucharitakul, N. J. Goble, U. R. Kumar, R. Sankar, Z. A. Bogorad, F. C. Chou, Y. T. Chen, and X. P. A. Gao, “Intrinsic Electron Mobility Exceeding 103 cm2/(V s) in Multilayer InSe FETs”, Nano Lett., Vol. 15, No. 6, pp. 3815-3819, 2015.

[https://doi.org/10.1021/acs.nanolett.5b00493]

-

J. Kim, S. Kim, Y. S. Cho, M. Choi, S. H. Jung, J. H. Cho, D. Whang, and J. Kang, “Solution-Processed MoS2 Film with Functional Interfaces via Precursor-Assisted Chemical Welding”, ACS Appl. Mater. Interfaces, Vol. 13, No. 10, pp. 12221-12229, 2021.

[https://doi.org/10.1021/acsami.1c00159]

-

Y. S. Cho, D. Rhee, H. J. Kim, H. S. Kim, J. M. Baik, and J. Kang, “Solution-Processed Graphene Thin-Film Enables Binder-Free, Efficient Loading of Nanocatalysts for Electrochemical Water Splitting”, Adv. Mater. Interfaces, Vol. 8, No. 23, p. 2101576, 2021.

[https://doi.org/10.1002/admi.202101576]