Short Review on Quartz Crystal Microbalance Sensors for Physical, Chemical, and Biological Applications

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License(https://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Quartz crystal microbalance (QCM) based sensors are used for various applications owing to advantages such as excellent accuracy and precision, rapid response, and tiny footprint. Traditional applications of QCM-based sensors include biological sensing and thin-film thickness monitoring. Recently, QCMs have been used as functional material for novel physical and chemical detections, and with improved device design. QCM-based sensors are garnering considerable attention in particulate matter sensing and electric nose application. This review covers the challenges and solutions in physical, chemical, and biological sensing applications. First, various physical sensing applications are introduced. Secondly, the toxic gas and chemical detection studies are outlined, focusing on introducing a coating method for uniform sensing film and sensing materials for a minimal damping effect. Lastly, the biological and medical sensing applications, which use the monomolecularly decorating method for biomolecule recognition and a brief description of the overall measuring system, are also discussed.

Keywords:

Quartz crystal microbalance, Physical sensor, Chemical sensor, Biological sensor1. INTRODUCTION

Micro electromechanical systems (MEMS) based sensors have drawn considerable attention owing to their compact sizes, high measurement sensitivity, fast response, and low detection limit. Among various MEMS platforms, resonators in suspended membrane and cantilever forms can directly measure the thermal, electrical, and magnetic events with outstanding resolution [1-3]. Such environmental parameters affect the dynamic response of a resonator, inducing a shift in resonant frequency (f0), deflection amplitude, and quality factor (Q). As the terms mentioned above depend on the change in mass, stiffness of the resonator, and damping from the surroundings, MEMS resonant sensors are becoming popular in the commercial sensor market.

MEMS resonant sensors are actuated using electrostatic, capacitive, thermal, capillary, or piezoelectric forces. Specifically, piezoelectric MEMS resonators are complementary with metal–oxide–semiconductors (CMOSs) [4, 5]. In addition, the integrated piezoelectric component can be utilized as the actuator and receiver (or sensing element), thus reducing the footprint and accompanying electronics. The analog output from the piezoelectric resonators can be acquired using an impedance analyzer, oscilloscope, or vector network analyzer. One can also easily track the frequency shift using a frequency counter or oscillator system embedding the resonator. Various types of piezoelectric MEMS resonators, such as quartz crystal microbalance (QCM), contour mode resonator (CMR), bulk acoustic wave resonator (BAWR), thin-film bulk acoustic resonator (FBAR), and surface acoustic wave resonator (SAWR), have been developed [6-9]. The dynamic properties of piezoelectric resonators can be finely tuned at the design level, as the frequency behavior depends on the piezoelectric layer thickness, spacing of electrodes, and operating modes. The list of suitable piezoelectric materials keeps increasing, including quartz, lead zirconate titanate (PZT), polyvinylidene fluoride (PVDF), zinc oxide (ZnO), lithium niobate (LiNbO3), and aluminum nitride (AlN), while some can be deposited using a sputter deposition tool over a large area [10-12].

Quartz with excellent purity is abundant in nature and can be easily manufactured using conventional micromachining techniques. Specifically, AT-cut quartz exhibits outstanding temperature stability, low noise, high purity, and a wide operating frequency range from kHz up to hundreds of MHz, ensuring the development of a high-performance sensor. One of the largest areas of quartz applications is using them in frequency filters, clocks, and antennas [13, 14]. QCMs have also been commercially successful, especially in biological sensing and thin-film thickness monitoring in semiconductor deposition processes. Beyond biological sensing, QCMs have been used for mass sensing nano/microparticulate matters and chemical sensing with an adequate integration of functional nanomaterials. Such sensing materials can be patterned on the surface of QCM via thin-film sputtering, spin-coating, dip-coating, electrospray deposition, direct growth, electrospinning, transfer-printing, and electroplating [15, 16]. In addition, materials such as semiconductor oxides, perovskites, metal-organic frameworks (MOF), carbon nanomaterials (CNT, graphene, graphene oxide), and transitional metal chalcogenides (TMDCs) can ensure high measurement sensitivity and selectivity [17-19].

Although QCMs have a long history, the recent advancements in sensing materials and their integration methods have enabled various new applications, such as fine dust monitors, chemical sensor arrays, portable medical diagnostic systems, and self-powered environment sensors. This mini-review provides the recent advances of QCM-based sensors for physical, chemical, and biological applications, especially focusing on recent studies and demonstrations in emerging application areas.

2. PHYSICAL SENSING APPLICATIONS

QCMs are widely used for physical sensing applications owing to their exceptional accuracy and precision. Successful applications of QCMs include a thickness monitoring system in metal deposition systems [17]. The resonant frequency of QCMs proportionally decreases with the thickness of the deposited metal film. Therefore, this system enables the deposition of a thin metal film with an accurately controlled thickness. However, for particle and liquid sensing applications, the damping effect, blockage of electric field penetration, and nonuniform mass sensitivity distribution induce an unreliable response. Therefore, there have been many efforts to overcome such limitations.

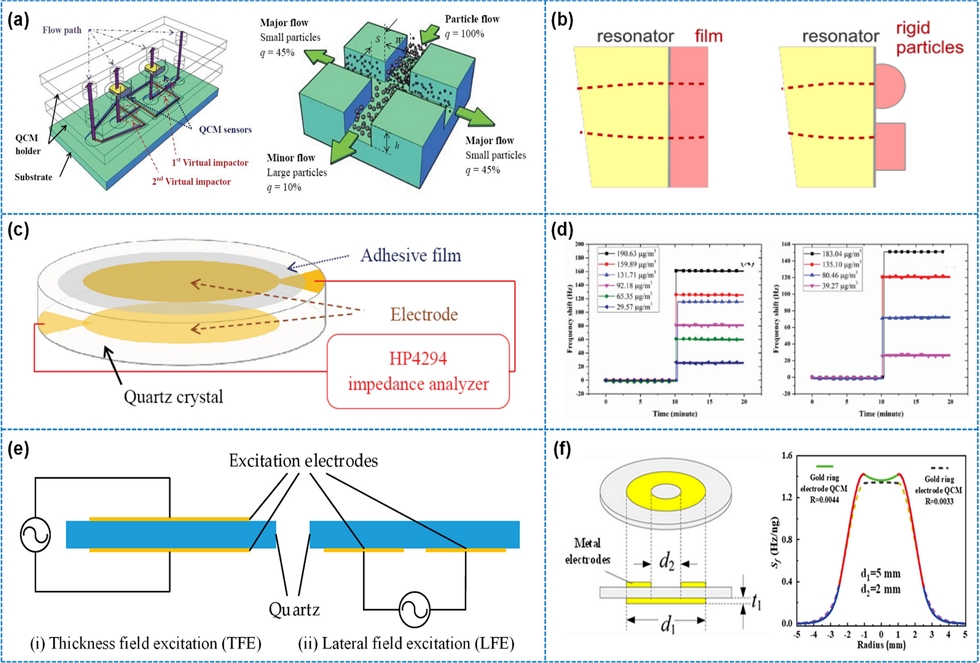

Recently, researchers have exploited QCM as a particle sensor. In particular, QCMs have great potential for a miniaturized particle sensing system owing to their tiny footprint [18-21]. Fig. 1 (a) shows the miniaturized particle sensing system through the combination of aerosol and MEMS technologies [22]. This study designed a virtual impactor for particle size separation and particle collection. Here, the virtual impactor effectively separates the particle without particle bouncing issues.

Physical Sensing: (a) Miniaturized particle collection and sensing system using virtual impactor system. Reprinted with permission form Ref. [22]. Copyright (2010) MDPI. (b) Shear wave formation depending on interfacial conditions. Reprinted with permission form Ref. [23]. Copyright (2021) MDPI. (c) Adhesive film coated QCM for efficient particle collection and rigid attachment. Reprinted with permission form Ref. [22]. Copyright (2010) MDPI. (d) Sensing response of PM 2.5 mass concentration using electrostatic particle collector based QCM. Reprinted with permission form Ref. [26]. Copyright (2019) IEEE Xplore. (e) Electrode configurations for tuning of electric field penetration into medium. Reprinted with permission from Ref. [27]. Copyright (2019) MDPI. (f) Ring electrode for a uniform mass sensitivity. Reprinted with permission from Ref. [12]. Copyright (2022) MDPI.

Compared to thickness monitoring systems, particle sensors have two main issues: nonuniform deposition and unperfect interfacial adhesion. As shown in Fig. 1 (b), particles deposit with nonuniform patterns owing to the surface charge effect, coffee ring effect, and unwanted fluidic motion [23, 24]. In addition, interfacial adhesion between particles and QCM would be weak owing to low Van der Waals forces. These issues induce significant damping, ultimately deteriorating the resonance quality of QCM. The adhesive film is coated on the QCM sensor to address the issues mentioned earlier, as shown in Fig. 1 (c) [22, 25]. An adhesive film allows for efficient particle collection and high adhesion, leading to minimized damping. Fig. 1 (d) shows the sensing response of the PM 2.5 mass concentration using an electrostatic particle collector-based QCM [26]. Here, an electrostatic particle collector enables uniform particle deposition as the charged particles repel each other.

The electrode configuration of QCM has been studied for improved sensing performance. Fig. 1 (e) shows the lateral field excitation (LFE)-QCM for liquid sensing applications [27]. An LFE-QCM allows the electric field to penetrate the testing liquid, thus enabling liquid viscosity and density measurements. Additionally, Fig. 1 (f) shows the ring-electrode configuration for the uniform mass sensitivity distribution [28]. In general, the mass sensitivity of a QCM has a Gaussian distribution. However, the ring electrode configuration has uniform mass sensitivity owing to optimal electric field formation, leading to reliable sensing application regardless of the patterns of the deposited materials.

3. CHEMICAL SENSING APPLICATIONS

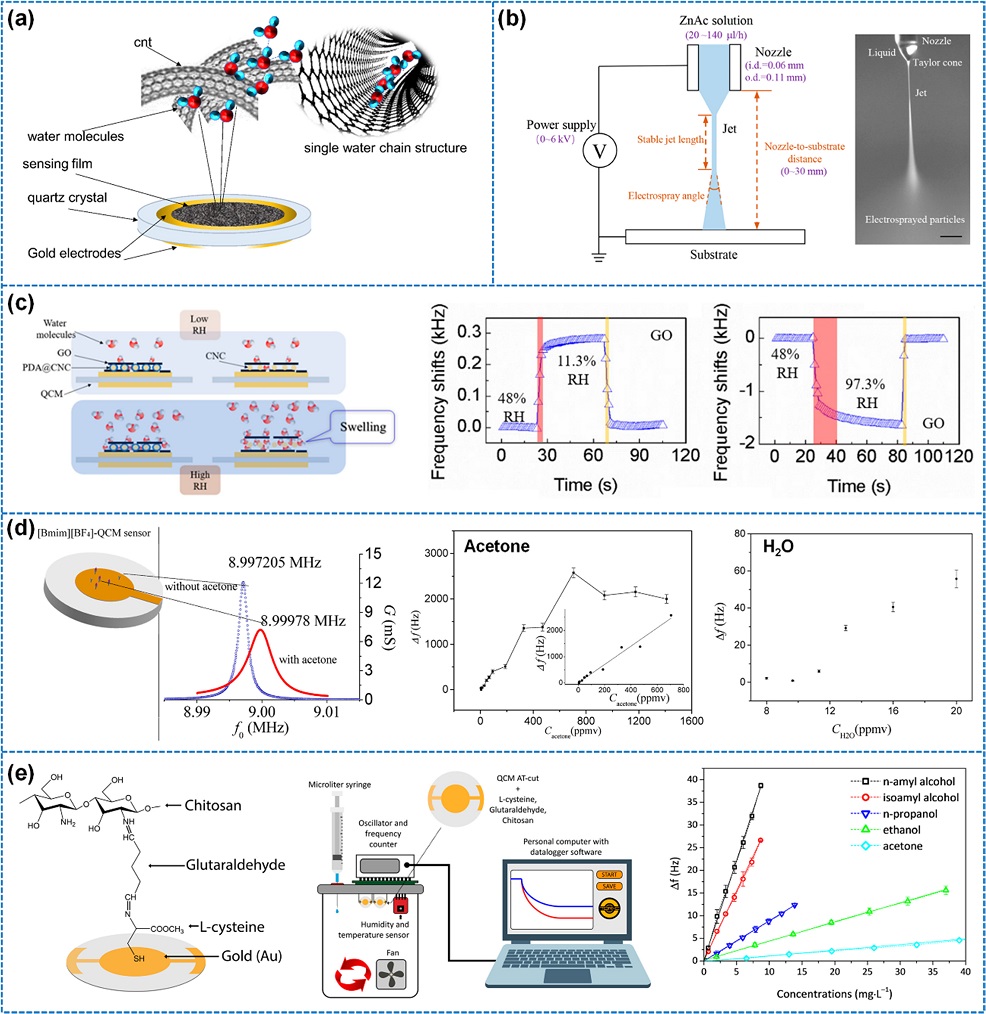

A QCM has been applied for gas sensing [29-32]. The gas sensor requires the sensing film to selectively capture a target species from a gas mixture, as shown in Fig. 2 (a) [33]. Many researchers have focused on the development of high-performance gas sensing systems. The heating system has been proposed for rapid gas interaction kinetics and high sensitivity [34]. In addition, the electro-spraying system has been proposed as a sensing material coating method, as the uniform sensing film ensures the efficient adsorption of a target gas with minimal damping [35]. Fig. 2 (b) shows the electro-spraying system for the uniform sensing layer [36]. This system exploits the high electric field to separate the solution into many droplets. For example, when a high electric field is applied to the solution, the excessive electrical energy on the surface of the solution leads to the generation of micrometer-scaled droplets. Then, the generated droplets travel along an electric field while the unipolar droplets electrically repel each other. Therefore, sprayed droplets uniformly and selectively deposit on the grounded electrode. Moreover, the electros praying system precisely controls the sensing film mass by adjusting the flow rate and monitoring the frequency shift of QCM. The uniform sensing film minimizes the interfacial loss at the interface sensing film and QCM.

Chemical Sensing: (a) Sensing material decorated QCM for a gas sensing application. Reprinted with permission form Ref. [33]. Copyright (2022) MDPI. (b) Elect spraying system for the uniform sensing film. Reprinted with permission from Ref. [36]. Copyright (2018) MDPI. (c) Graphene oxide coated QCM and (d) sensing response for a humidity sensing. Reprinted with permission form Ref. [37]. Copyright (2020) MDPI. (e) Acetone sensing using QCM. Reprinted with permission form Ref. [38]. Copyright (2017) MDPI. (f) Alcohol sensing application using QCM. Reprinted with permission from Ref. [40]. Copyright (2018) MDPI.

For viscous target materials such as humidity, accumulated target materials induce a significant damping effect. Graphene oxide has drawn much attention as a humidity-sensing film. Graphene oxide has an abundant hydroxyl group on its body, which captures water molecules, while its majority consists of a hydrophobic six-hexagonal carbon ring. Therefore, graphene oxide efficiently captures water molecules without significant damping, as shown in Fig. 2 (c-d) [37]. Recently, the QCM gas sensing application has been extended to detect hazardous gases such as volatile organic compounds (VOC), as shown in Fig. 2 (e-f) [38-40]. MOFs have drawn much attention as a VOC sensing material owing to its significant surface area.

4. BIOLOGICAL SENSING APPLICATIONS

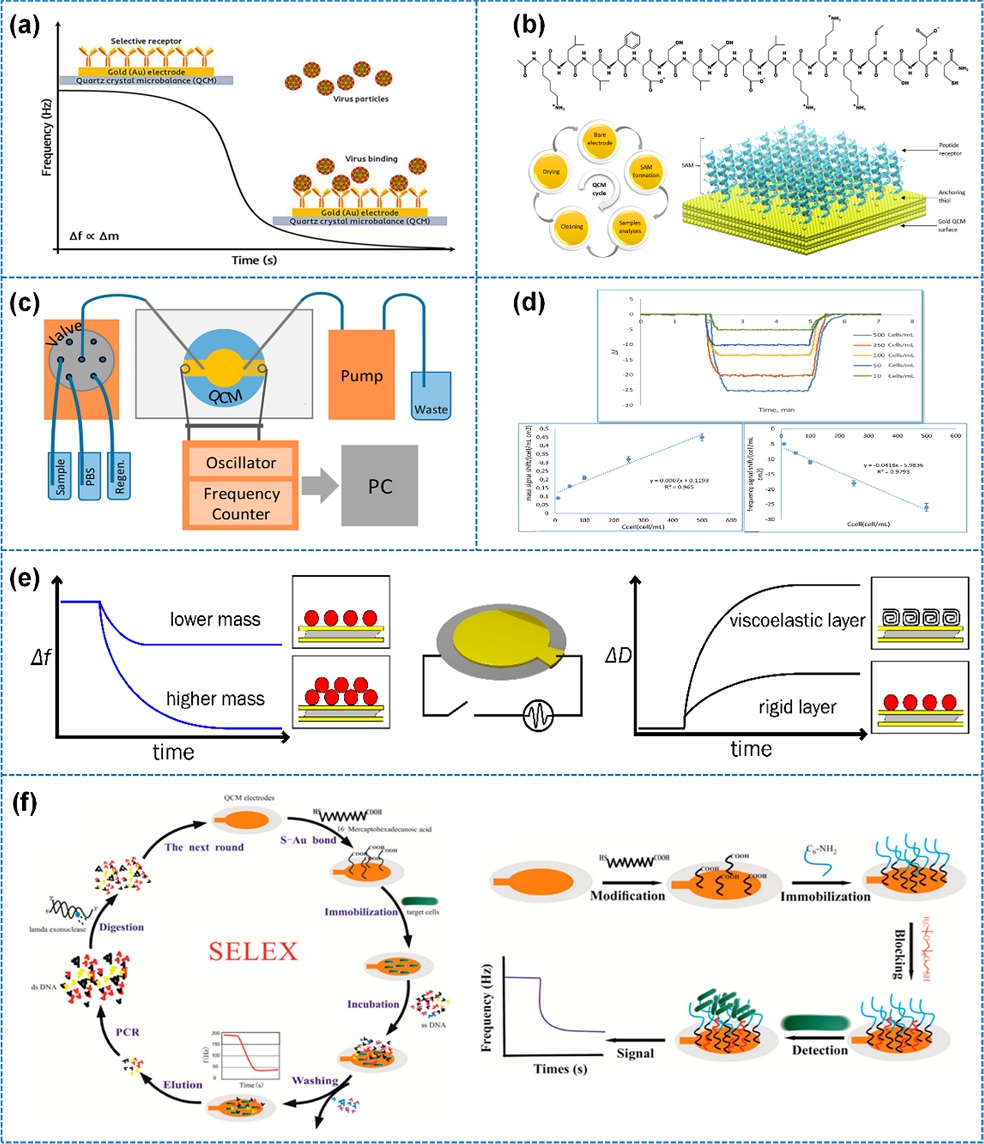

A QCM device has been applied as a transducer for a biological sensing system [41-46]. Fig. 3 (a) shows the biological sensing scheme using QCM [47]. The receptor is monomolecularly layered on a QCM electrode to immobilize biomolecules. Before decorating the receptor, an electrode surface is functionalized by attaching a functional group (for example, thiols, sulfides, disulfides, etc.) to immobilize the receptor. The receptor and functional group are decorated as ordered monomolecular layers through a self-assembly monolayer (SAM), as shown in Fig. 3 (b) [48]. Fig. 3 (c) shows the experimental setup used to measure biomolecules in a biofluid [49]. The microfluidic system allows the biofluid to flow through the sensing area of QCM. The receptor immobilizes the recognition biomolecules, leading to a resonant frequency shift of QCM owing to mass loading. The oscillator and frequency counter system monitor and track the resonant frequency of QCM. This system enables real-time sensing with a high accuracy and resolution, as shown in Fig. 3 (d) [50].

Biological Sensing: (a) a virus sensing scheme using QCM. Reprinted with permission form Ref. [47]. Copyright (2017) MDPI. (b) Schematic view of SAM formation for a surface functionalization. Reprinted with permission form Ref. [48]. Copyright (2022) MDPI. (c) Experimental setup of biofluidic sensing system. Reprinted with permission form Ref. [49]. Copyright (2014) MDPI. (d) Real-time response for breast cancer cell. Reprinted with permission form Ref. [50]. Copyright (2021) MDPI. (e) Schematic view of QCM-D system to monitor the viscoelastic behavior of polymeric film. Reprinted with permission form Ref. [55]. Copyright (2022) MDPI. (f) a SELEX process for an aptamer selection and immobilization of aptamers on QCM. Reprinted with permission form Ref. [56]. Copyright (2022) MDPI

Immobilizing biomolecules or forming molecularly imprinted polymers are essential in the design biological sensing platform [51-53]. Therefore, the real-time monitoring of the physical and chemical alterations of the polymeric film in the sensing area is required to achieve a reliable sensing platform. A general QCM measures the resonant frequency shift and calculates the added mass using the Sauerbrey equation [54]. However, such a system becomes unreliable when the viscoelastic behavior of a polymeric film is involved. Therefore, many researchers have presented a QCM-D system that can measure energy dissipation due to viscoelastic behavior and resonant frequency shifts, as shown in Fig. 3 (e) [55]. This system accurately measures the added mass by reflecting the shift in resonant frequency and energy dissipation. Further, energy dissipation gives valuable information such as film growth, adsorption of target materials, and film swelling.

The aptamer is a promising molecular recognition element. It is an artificial single-stranded oligonucleotide obtained through the systematic evolution of ligands by exponential enrichment (SELEX) in vitro. The aptamer is an economical receptor for biding target analytes owing to its simple manufacturing process, enabling mass production and ease of high-quality purification. Compared with antibodies, the aptamer maintains its properties at room temperature with high chemical stability, and their low surface density enables efficient recognition with minimal steric hindrance. Many researchers have integrated aptamer with a QCM capable of real-time, on-site, and label-free detection with high sensitivity, as shown in Fig. 3 (f) [56-58].

5. CONCLUSIONS

This review outlined QCM sensor-based physical, chemical, and biosensor applications. A fine particle sensor was discussed as a representative physical sensing application. Many researchers focused on adhesive films to collect and attach particles efficiently. In addition, a MEMS-based impactor system was used as a miniaturized particle sensing platform. Secondly, gas sensing technologies were introduced as examples of chemical sensing applications. The uniformity of a sensing film and viscous effect due to accumulated gas molecules were critical issues in a gas sensing field. The previous study exploited the electro-spraying system to decorate a sensing film uniformly. In addition, graphene oxide attracted significant attention for minimizing the damping effect due to accumulated gas molecules owing to its unique structures. Lastly, a QCM has great potential for biological sensing applications owing to rapid, accurate, and precise sensing performance. The QCM electrode was functionalized with a monomolecular functional group for biomolecule recognition through SAM. This QCM sensor was integrated with resonant measuring instruments and a biofluidic system, enabling a rapid detecting system.

Acknowledgments

This work was supported by KIMM Institutional Program (NK236F) and NST/KIMM.

REFERENCES

-

F. Butti, P. Bruschi, M. Dei, and M. Piotto, “A compact instrumentation amplifier for MEMS thermal sensor interfacing”, Analog Integrat. Circuits Signal Process., Vol. 72, No. 3, pp. 585-594, 2012.

[https://doi.org/10.1007/s10470-011-9661-2]

-

Q. Ma, K. Huang, Z. Yu, and Z. Wang, “A MEMS-based electric field sensor for measurement of high-voltage DC synthetic fields in air”, IEEE Sens. J., Vol. 17, No. 23, pp. 7866-7876, 2017.

[https://doi.org/10.1109/JSEN.2017.2762327]

- J. Lan and Y. Shi, “Vehicle detection and recognition based on a MEMS magnetic sensor”, in 2009 4th IEEE Int. Conf. Nano/Micro Eng. Mol. Syst., pp. 404-408, 2019.

-

H. Liu, L. Zhang, K. H. H. Li, and O. K. Tan, “Microhotplates for metal oxide semiconductor gas sensor applications—Towards the CMOS-MEMS monolithic approach”, Micromachines, Vol. 9, No. 11, pp. 557(1)-557(24), 2018.

[https://doi.org/10.3390/mi9110557]

-

H. Qu, “CMOS MEMS fabrication technologies and devices”, Micromachines, Vol. 7, No. 1, pp. 14(1)-14(21), 2016.

[https://doi.org/10.3390/mi7010014]

-

H. J. Kim, S. I. Jung, J. Segovia-Fernandez, and G. Piazza, “The impact of electrode materials on 1/f noise in piezoelectric AlN contour mode resonators”, AIP Adv., Vol. 8, No. 5, pp. 055009(1)-055009(8), 2018.

[https://doi.org/10.1063/1.5024961]

-

V. M. Mecea, “From Quartz Crystal Microbalance to Fundamental Principles of Mass Measurements,” Anal. Lett., Vol. 38, No. 5, pp. 753-767, 2005.

[https://doi.org/10.1081/AL-200056171]

-

J. Zheng, J. Zhou, P. Zeng, Y. Liu, Y. Shen, W. Yao, Z. Chen, J. Wu, S. Xiong, Y. Chen, X. Shi, J. Liu, Y. Fu, and H. Duan, “30 GHz surface acoustic wave transducers with extremely high mass sensitivity,” Appl. Phys. Lett., Vol. 116, No. 12, p. 123502, 2020.

[https://doi.org/10.1063/1.5142673]

-

H. Seh, T. Hyodo, and H. L. Tuller, “Bulk acoustic wave resonator as a sensing platform for NOx at high temperatures”, Sens. Actuators B: Chem., Vol. 108, No. 1-2, pp. 547-552, 2005.

[https://doi.org/10.1016/j.snb.2004.11.083]

-

A. Kochhar, A. Mahmoud, Y. Shen, N. Turumella, and G. Piazza, “X-Cut Lithium Niobate-Based Shear Horizontal Resonators for Radio Frequency Applications”, J. Microelectromech. Syst., Vol. 29, No. 6, pp. 1464-1472, 2020.

[https://doi.org/10.1109/JMEMS.2020.3026167]

-

J. C. Doll, B. C. Petzold, B. Ninan, R. Mullapudi, and B. L. Pruitt, “Aluminum nitride on titanium for CMOS compatible piezoelectric transducers”, J. Micromech. Microeng., Vol. 20, No. 2, p. 025008, 2009.

[https://doi.org/10.1088/0960-1317/20/2/025008]

-

Z. Xu and Z. Li, “Dynamic humidity response of surface acoustic wave sensors based on zinc oxide nanoparticles sensitive film”, Appl. Phys. A, Vol. 127, No. 6, pp. 1-7, 2021.

[https://doi.org/10.1007/s00339-021-04587-6]

-

C. Lam, “A review of the recent development of MEMS and crystal oscillators and their impacts on the frequency control products industry”, in 2008 IEEE Ultrason. Symp., pp. 694-704, 2008.

[https://doi.org/10.1109/ULTSYM.2008.0167]

-

B. Murashov and Y. P. Tsvetkov, “Instrument for checking quartz-crystal oscillators with standard frequency signals in the long-wave and very-long-wave ranges”, Meas. Tech., Vol. 19, No. 7, pp. 1012-1015, 1976.

[https://doi.org/10.1007/BF00821917]

-

A. Javadi, A. Solouk, M. H. Nazarpak, and F. Bagheri, “Surface engineering of titanium-based implants using electro-spraying and dip coating methods”, Mater. Sci. Eng. C, Vol. 99, pp. 620-630, 2019.

[https://doi.org/10.1016/j.msec.2019.01.027]

-

S. K. Boda, X. Li, and J. Xie, “Electrospraying an enabling technology for pharmaceutical and biomedical applications: A review”, J. Aerosol Sci., Vol. 125, pp. 164-181, 2018.

[https://doi.org/10.1016/j.jaerosci.2018.04.002]

-

A. Wajid, “On the accuracy of the quartz-crystal microbalance (QCM) in thin-film depositions”, Sens. Actuators a: Phys., Vol. 63, No. 1, pp. 41-46, 1997.

[https://doi.org/10.1016/S0924-4247(97)80427-X]

-

M. Chen, F. J. Romay, L. Li, A. Naqwi, and V. A. Marple, “A novel quartz crystal cascade impactor for real-time aerosol mass distribution measurement”, Aerosol Sci. Technol., Vol. 50, No. 9, pp. 971-983, 2016.

[https://doi.org/10.1080/02786826.2016.1213790]

-

J.-S. Choi and W.-T. Park, “MEMS particle sensor based on resonant frequency shifting”, Micro Nano Syst. Lett., Vol. 8, No. 1, pp. 1-6, 2020.

[https://doi.org/10.1186/s40486-020-00118-9]

-

U. Soysal, E. Géhin, E. Algré, B. Berthelot, G. Da, and E. Robine, “Aerosol mass concentration measurements: Recent advancements of real-time nano/micro systems”, J. Aerosol Sci., Vol. 114, pp. 42-54, 2017.

[https://doi.org/10.1016/j.jaerosci.2017.09.008]

-

J. Zhao, M. Liu, L. Liang, W. Wang, and J. Xie, “Airborne particulate matter classification and concentration detection based on 3D printed virtual impactor and quartz crystal microbalance sensor”, Sens. Actuators A: Phys., Vol. 238, pp. 379-388, 2016.

[https://doi.org/10.1016/j.sna.2015.12.029]

-

D. Liang, W.-P. Shih, C.-S. Chen, and C.-A. Dai, “A miniature system for separating aerosol particles and measuring mass concentrations”, Sens., Vol. 10, No. 4, pp. 3641-3654, 2010.

[https://doi.org/10.3390/s100403641]

-

D. Johannsmann, A. Langhoff, and C. Leppin, “Studying soft interfaces with shear waves: Principles and applications of the Quartz Crystal Microbalance (QCM)”, Sens., Vol. 21, No. 10, pp. 3490(1)-3490(79), 2021.

[https://doi.org/10.3390/s21103490]

-

I. R. Jang, J. Park, C. Ryu, S. I. Jung, H. N. Kim, S. B. Kim, and H. J. Kim, “High Precision Liquid Salinity Sensing Using a CNT Coated Quartz Crystal Microbalance”, IEEE Sens. J., Vol. 22, No. 8, pp. 7684-7691, 2022.

[https://doi.org/10.1109/JSEN.2022.3157465]

-

I. R. Jang, S. I. Jung, G. Lee, I. Park, S. B. Kim, and H. J. Kim, “Quartz crystal microbalance with thermally-controlled surface adhesion for an efficient fine dust collection and sensing”, J. Hazard.Mater., Vol. 424, p. 127560, 2022.

[https://doi.org/10.1016/j.jhazmat.2021.127560]

-

N. D. Ngo, J. Lee, M.-W. Kim, and J. Jang, “Measurement of PM 2.5 Mass Concentration Using an Electrostatic Particle Concentrator-Based Quartz Crystal Microbalance”, IEEE Access, Vol. 7, pp. 170640-170647, 2019.

[https://doi.org/10.1109/ACCESS.2019.2955377]

-

J. Liang, D. Kong, and C. Liu, “Study on Dual Channel Lateral Field Excitation Quartz Crystal Microbalance for Measuring Liquid Electrical Properties”, Sens., Vol. 19, No. 5, pp. 1253(1)-1253(11), 2019.

[https://doi.org/10.3390/s19051253]

-

X. Huang, Q. Chen, W. Pan, and Y. Yao, “Advances in the Mass Sensitivity Distribution of Quartz Crystal Microbalances: A Review”, Sens., Vol. 22, No. 14, pp. 5112(1)-5112(20), 2022.

[https://doi.org/10.3390/s22145112]

-

P. Sun, Y. Jiang, G. Xie, X. Du, and J. Hu, “A room temperature supramolecular-based quartz crystal microbalance (QCM) methane gas sensor”, Sens. Actuators B: Chem., Vol. 141, No. 1, pp. 104-108, 2009.

[https://doi.org/10.1016/j.snb.2009.06.012]

-

W. Chen, F. Deng, M. Xu, J. Wang, Z. Wei, and Y. Wang, “GO/Cu2O nanocomposite based QCM gas sensor for trimethylamine detection under low concentrations”, Sens Actuators B: Chem., Vol. 273, pp. 498-504, 2018.

[https://doi.org/10.1016/j.snb.2018.06.062]

-

T. Addabbo, A. Fort, M. Mugnaini, V. Vignoli, A. Baldi, and M. Bruzzi, “Quartz-crystal microbalance gas sensors based on TiO 2 nanoparticles”, EEE Trans. Instrum. Meas., Vol. 67, No. 3, pp. 722-730, 2018.

[https://doi.org/10.1109/TIM.2017.2785118]

-

M. Matsuguchi and Y. Kadowaki, “Poly (acrylamide) derivatives for QCM-based HCl gas sensor applications”, Sens. Actuators B: Chem., Vol. 130, No. 2, pp. 842-847, 2008.

[https://doi.org/10.1016/j.snb.2007.10.049]

-

A. Fort, A. Lo Grasso, M. Mugnaini, E. Panzardi, and V. Vignoli, “QCM Measurements of RH with Nanostructured Carbon-Based Materials: Part 1—Theory and Model”, Chemosensors, Vol. 10, No. 8, pp. 315(1)-315(13), 2022.

[https://doi.org/10.3390/chemosensors10080315]

-

P. Bhattacharyya, “Technological journey towards reliable microheater development for MEMS gas sensors: A review”, IEEE Trans. Device Mater. Reliab., Vol. 14, No. 2, pp. 589-599, 2014.

[https://doi.org/10.1109/TDMR.2014.2311801]

-

I. R. Jang, S. I. Jung, J. Park, C. Ryu, I. Park, S. B. Kim, and H. J. Kim, “Direct and controlled device integration of graphene oxide on Quartz Crystal Microbalance via electrospray deposition for stable humidity sensing”, Ceram. Int., Vol. 48, No. 6, pp. 8004-8011, 2021.

[https://doi.org/10.1016/j.ceramint.2021.11.347]

-

W. Li, J. Lin, X. Wang, J. Jiang, S. Guo, and G. Zheng, “Electrospray deposition of ZnO thin films and its application to gas sensors”, Micromachines, Vol. 9, No. 2, pp. 66(1)-66(7), 2018.

[https://doi.org/10.3390/mi9020066]

-

Y. Yao, X. Huang, Q. Chen, Z. Zhang, and W. Ling, “High sensitivity and high stability QCM humidity sensors based on polydopamine coated cellulose nanocrystals/graphene oxide nanocomposite”, Nanomater., Vol. 10, No. 11, pp. 2210(1)-2210(12), 2020.

[https://doi.org/10.3390/nano10112210]

-

W. Tao, P. Lin, S. Liu, Q. Xie, S. Ke, and X. Zeng, “1-butyl-3-methylimidazolium tetrafluoroborate film as a highly selective sensing material for non-invasive detection of acetone using a quartz crystal microbalance”, Sens., Vol. 17, No. 1, pp. 194(1)-194(12), 2017.

[https://doi.org/10.3390/s17010194]

-

E. Oleneva, T. Kuchmenko, E. Drozdova, A. Legin, and D. Kirsanov, “Identification of plastic toys contaminated with volatile organic compounds using QCM gas sensor array”, Talanta, Vol. 211, p. 120701, 2020.

[https://doi.org/10.1016/j.talanta.2019.120701]

-

K. Triyana, A. Sembiring, A. Rianjanu, S. N. Hidayat, R. Riowirawan, T. Julian, A. Kusumaatmaja, I. Santoso, and R. Roto, “Chitosan-based quartz crystal microbalance for alcohol sensing”, Electron., Vol. 7, No. 9, pp. 181(1)-181(11), 2018.

[https://doi.org/10.3390/electronics7090181]

-

I. Mannelli, M. Minunni, S. Tombelli, and M. Mascini, “Quartz crystal microbalance (QCM) affinity biosensor for genetically modified organisms (GMOs) detection”, Biosens. bioelectron., Vol. 18, No. 2-3, pp. 129-140, 2003.

[https://doi.org/10.1016/S0956-5663(02)00166-5]

-

R. Z. Hao, H. B. Song, G. M. Zuo, R. F. Yang, H. P. Wei, D. B. Wang, Z. Q. Cuia, Z. P. Zhang, Z. X. Cheng, and X. E. Zhang, “DNA probe functionalized QCM biosensor based on gold nanoparticle amplification for Bacillus anthracis detection”, Biosens. Bioelectron., Vol. 26, No. 8, pp. 3398-3404, 2011.

[https://doi.org/10.1016/j.bios.2011.01.010]

-

M. Z. Atashbar, B. Bejcek, A. Vijh, and S. Singamaneni, “QCM biosensor with ultra thin polymer film”, Sens. Actuators B: Chem., Vol. 107, No. 2, pp. 945-951, 2005.

[https://doi.org/10.1016/j.snb.2004.12.047]

-

S.-R. Hong, H.-D. Jeong, and S. Hong, “QCM DNA biosensor for the diagnosis of a fish pathogenic virus VHSV”, Talanta, Vol. 82, No. 3, pp. 899-903, 2010.

[https://doi.org/10.1016/j.talanta.2010.04.065]

-

M. Lazerges, H. Perrot, N. Zeghib, E. Antoine, and C. Compere, “In situ QCM DNA-biosensor probe modification”, Sens. Actuators B: Chem., Vol. 120, No. 1, pp. 329-337, 2006.

[https://doi.org/10.1016/j.snb.2006.02.024]

-

C. Zhang, G. Feng, and Z. Gao, “Development of a new kind of dual modulated QCM biosensor”, Biosens. Bioelectron., Vol. 12, No. 12, pp. 1219-1225, 1997.

[https://doi.org/10.1016/S0956-5663(97)00065-1]

-

A. Afzal, A. Mujahid, R. Schirhagl, S. Z. Bajwa, U. Latif, and S. Feroz, “Gravimetric viral diagnostics: QCM based biosensors for early detection of viruses”, Chemosensors, Vol. 5, No. 1, pp. 7(1)-7(25), 2017.

[https://doi.org/10.3390/chemosensors5010007]

-

T. Wasilewski, B. Szulczyński, D. Dobrzyniewski, W. Jakubaszek, J. Gębicki, and W. Kamysz, “Development and Assessment of Regeneration Methods for Peptide-Based QCM Biosensors in VOCs Analysis Applications”, Biosens., Vol. 12, No. 5, pp. 309(1)-309(14), 2022.

[https://doi.org/10.3390/bios12050309]

-

Z. Farka, D. Kovář, and P. Skládal, “Rapid detection of microorganisms based on active and passive modes of QCM”, Sens., Vol. 15, No. 1, pp. 79-92, 2014.

[https://doi.org/10.3390/s150100079]

-

M. Yılmaz, M. Bakhshpour, I. Gökturk, A. K. Pişkin, and A. Denizli, “Quartz crystal microbalance (QCM) based biosensor functionalized by HER2/Neu antibody for breast cancer cell detection”, Chemosensors, Vol. 9, No. 4, pp. 80(1)-80(15), 2021.

[https://doi.org/10.3390/chemosensors9040080]

-

V. Ratautaite, S. N. Topkaya, L. Mikoliunaite, M. Ozsoz, Y. Oztekin, A. Ramanaviciene, and A. Ramanavicius, “Molecularly imprinted polypyrrole for DNA determination”, Electroanalysis, Vol. 25, No. 5, pp. 1169-1177, 2013.

[https://doi.org/10.1002/elan.201300063]

-

I. Baleviciute, V. Ratautaite, A. Ramanaviciene, Z. Balevicius, J. Broeders, D. Croux, M. McDonald, F. Vahidpour, R. Thoelen, W. D. Ceuninck, K. Haenen, M. Nesladek, A. Reza, and A. Ramanavicius, “Evaluation of theophylline imprinted polypyrrole film”, Synthetic Metals, Vol. 209, pp. 206-211, 2015.

[https://doi.org/10.1016/j.synthmet.2015.07.021]

-

V. Ratautaite, D. Plausinaitis, I. Baleviciute, L. Mikoliunaite, A. Ramanaviciene, and A. Ramanavicius, “Characterization of caffeine-imprinted polypyrrole by a quartz crystal microbalance and electrochemical impedance spectroscopy”, Sens. Actuators B: Chem., Vol. 212, pp. 63-71, 2015.

[https://doi.org/10.1016/j.snb.2015.01.109]

-

G. Sauerbrey, “Verwendung von Schwingquarzen zur Wagung dunner Schichten und zur Mikrowagung”, Zeitschrift für physik, Vol. 155, No. 2, pp. 206-222, 1959.

[https://doi.org/10.1007/BF01337937]

-

I. Plikusiene, V. Maciulis, A. Ramanavicius, and A. Ramanaviciene, “Spectroscopic Ellipsometry and Quartz Crystal Microbalance with Dissipation for the Assessment of Polymer Layers and for the Application in Biosensing”, Polym., Vol. 14, No. 5, p. 1056(1)-1056(21), 2022.

[https://doi.org/10.3390/polym14051056]

-

S. Akgönüllü, E. Özgur, and A. Denizli, “Quartz Crystal Microbalance-Based Aptasensors for Medical Diagnosis”, Micromachines, Vol. 13, No. 9, p. 1441(1)-1441(18), 2022.

[https://doi.org/10.3390/mi13091441]

-

W. Shan, Y. Pan, H. Fang, M. Guo, Z. Nie, Y. Huang, and S. Yao., “An aptamer-based quartz crystal microbalance biosensor for sensitive and selective detection of leukemia cells using silver-enhanced gold nanoparticle label”, Talanta, Vol. 126, pp. 130-135, 2014.

[https://doi.org/10.1016/j.talanta.2014.03.056]

-

L. Wang, R. Wang, F. Chen, T. Jiang, H. Wang, M. Slavik, H. Wei, and Y. Li, “QCM-based aptamer selection and detection of Salmonella typhimurium”, Food chemistry, Vol. 221, pp. 776-782, 2017.

[https://doi.org/10.1016/j.foodchem.2016.11.104]