Brief Review of Lead-Free Piezoelectric Ceramics for High-Power Applications

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License(https://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Lead-free piezoelectric ceramics have gained significant attention as environmentally friendly alternatives to leadbased materials such as Pb(Zr,Ti)O3 (PZT) for high-power applications. This review focuses on three prominent lead-free ceramic systems: BaTiO3 (BT), Bi0.5Na0.5TiO3 (BNT), and (Na0.5K0.5)NbO3 (NKN). BT-based ceramics offer excellent piezoelectric properties but are limited by their low Curie temperatures, which has been addressed through doping and sintering aids such as Li2O. BNT-based ceramics exhibit high thermal stabilities and tunable electromechanical properties; however, challenges remain because of their relatively low piezoelectric coefficients. NKN-based ceramics demonstrate outstanding mechanical quality factors (Qm) and high Curie temperatures, with significant performance improvements achieved through CuO doping and co-doping with other oxides. Despite these advancements, issues such as thermal stability, alkaline element volatility, and limited d33 still need to be resolved. Continued progress in doping strategies, microstructural control, and advanced processing techniques will be crucial to fully unlock the potential of lead-free piezoelectric ceramics for high-power applications.

Keywords:

Lead-free piezoelectric ceramics, High-power applications, Mechanical quality factor (Qm), Doping strategies1. INTRODUCTION

Piezoelectric materials play a pivotal role in modern electronics and industrial technologies, especially in highpower applications [1-3]. Devices such as ultrasonic transducers, piezoelectric transformers, and sonar systems demand high precision and energy efficiency [4-6]. Piezoelectric materials, which convert electrical energy into mechanical energy and vice versa, are the core components of high-performance devices. The stability and reliability of piezoelectric materials are critical for high-power applications. Piezoelectric ceramics are broadly categorized into two main types: “soft ceramics” and “hard ceramics.” Soft piezoelectric ceramics are characterized by high piezoelectric coefficients (d33) and sensitivity, making them suitable for sensors and low-power applications. By contrast, hard piezoelectric ceramics exhibit high mechanical quality factors (Qm) and low dielectric loss, which are essential for highpower applications [7].

High-power piezoelectric applications often require a combination of hard and soft properties. For high-power applications, achieving a balance between the mechanical stability and low energy loss of hard ceramics and the sensitivity and high energy-conversion efficiency of soft ceramics is critical. The harmonious integration of these properties is not only vital for efficient operation but also for ensuring stable and durable performance over time. Consequently, the development of piezoelectric materials that combine or optimize both characteristics remains a key challenge for high-power applications.

Environmental regulations and concerns about lead toxicity have incited research into lead-free piezoelectric ceramics as alternatives to lead-based materials, particularly Pb(Zr,Ti)O3 (PZT) [8-10]. The European Union’s Restriction of Hazardous Substances Directive has further emphasized the need to limit lead use in electronic products, accelerating the development of lead-free alternatives. Although PZT has been widely used owing to its exceptional electromechanical properties, environmental issues associated with lead have shifted attention to lead-free materials such as BaTiO3 (BT), (Bi0.5Na0.5)TiO3 (BNT), and (Na0.5K0.5)NbO3 (NKN) [11-13].

Research on lead-free piezoelectric ceramics has focused on achieving eco-friendly materials with high mechanical quality factors and piezoelectric coefficients suitable for high-power applications. These properties can be further enhanced through advanced doping strategies and microstructural control [14- 16]. Recent studies have highlighted the importance of texturing techniques that optimize the alignment of crystallographic grains to improve the electromechanical performance [17]. Texturing has emerged as a critical approach to enhancing the properties of lead-free hard ceramics, making it a key focus of contemporary research.

Current studies on lead-free piezoelectric ceramics primarily concern specific material systems such as BT, BNT, and NKN, each of which exhibits unique physical and chemical properties. Researchers have continued to improve their performance by employing various doping strategies and processing techniques. This review aims to provide a comprehensive analysis of lead-free hard piezoelectric ceramics and discuss their potential applications, existing limitations, and prospects for high-power devices. Finally, this study seeks to explore the commercial viability of lead-free piezoelectric ceramics for advanced technological applications.

2. BT-based High-power Piezoceramics

Barium titanate (BaTiO3), the first perovskite-structured piezoelectric material, has historically played a vital role in applications such as underwater transducers [18]. Although its widespread use has decreased with the advent of PZT ceramics, BT remains a prominent contender among leadfree piezoelectric materials owing to its exceptional electromechanical characteristics.

Pure BT ceramics produced using conventional solid-state methods typically exhibit a room temperature piezoelectric coefficient (d33) of approximately 180 pC/N. Efforts to enhance these properties have focused on alternative preparation techniques such as hydrothermal and microwave sintering methods [19-21]. However, these advanced techniques generally involve trade-offs such as reduced mechanical quality factors (Qm), which may limit their suitability for specific applications.

The sintering process for BT-based ceramics generally requires temperatures above 1300°C to achieve sufficient material density. Researchers have investigated the use of sintering aids to address this issue. For example, the addition of 1 mol% Li2O has demonstrated notable improvements in electromechanical properties, achieving a Qm of ~1405 and a d33 of ~255 pC/N. These modifications underscore the potential for tuning BT-based ceramics to meet specific application demands [11].

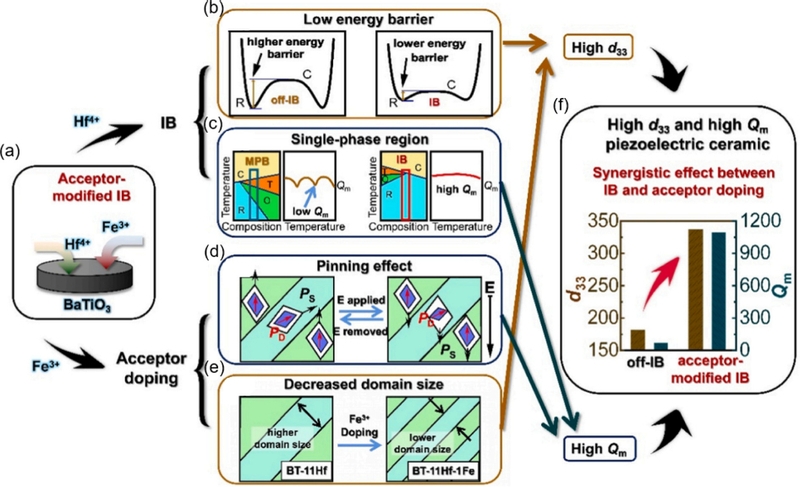

A recent study demonstrated that the tradeoff between the mechanical quality factor and piezoelectric coefficient in BaTiO3-based ceramics can be addressed using acceptormodified invisible boundary (IB) engineering, as shown in Fig. 1 [14]. By introducing Fe3+ dopants into BaTi0.89Hf0.11O3 ceramics, researchers achieved a remarkable combination of Qm ~1096 and d33 ~337 pC/N, outperforming many lead-free and lead-based piezoceramics. This approach leverages the low energy barrier for polarization rotation at the IB and pinning effect from acceptor doping, resulting in significant enhancements in electromechanical properties. However, the material suffers from a notably low Curie temperature (TC) of only 48°C, which severely limits its applicability in high-temperature environments. These findings highlight the potential of IB engineering for developing high-performance lead-free piezoelectric materials while emphasizing the critical need for strategies to improve TC for broader application viability.

Schematic of high Qm and high d33 from the acceptormodified IB. (a) Acceptor-modified IB was obtained in Hf4+ and Fe3+ doped BT ceramics. (b) IB composition has a lower energy barrier than that of the off-IB compositions, which leads to high d33. (c) IB composition is a single-phase state and favorable to Qm. (d) Acceptor doping generates a normal pinning effect, which is beneficial for improving Qm. (e) Acceptor doping can decrease domain size, which is beneficial to improve d33; (f) Piezoelectric ceramics with high d33 and high Qm can be obtained using the synergistic effect of the acceptor-modified IB. [14] Copyright (2025) Elsevier

One major limitation of BT-based ceramics is their relatively low Curie temperature (TC), which is often below 100°C, restricting their application in high-temperature environments. Doping strategies have been effective in overcoming this challenge. For instance, MnO2-doped BT ceramics have achieved a TC of 123°C with a moderate Qm of ~340.8. Similarly, MnCO3 doping has produced BT ceramics with an ultrahigh Qm of ~2400 and a TC of ~133°C using traditional sintering techniques [22,23].

Increasing the TC of BT-based ceramics remains a critical objective for their use in high-power applications. Advancements in doping and sintering methodologies hold promise for enhancing both the thermal and electromechanical properties of BT-based systems, enabling their broader adoption in demanding industrial and technological applications. The piezoelectric properties of BT, BNT, and NKN are summarized in Table 1.

3. BNT-based High-power Piezoceramics

Bismuth sodium titanate (Bi0.5Na0.5TiO3; BNT) was first identified by Smolensky et al. in 1960 [39]. At room temperature, BNT exhibits a rhombohedral symmetry (R phase) and a relatively high Curie temperature (TC) of approximately 320°C [40]. Given its potential for high-power applications, extensive efforts have been made to improve the electromechanical properties of BNT-based ceramics through doping strategies and optimized sintering processes to enhance their mechanical quali ty factor (Qm).

Pure BNT ceramics were reported to achieve a moderate Qm of ~366 and a low dielectric constant (εr) of ~345 at room temperature [41]. Structural and piezoelectric studies on Bi0.5(Na1−xLix)0.5TiO3 compositions indicated that doping with Li can slightly enhance Qm, with a maximum increase of ~30 observed at x=0.04 [42]. However, excessive Li doping leads to deteriorated properties, underscoring the delicate balance required in compositional modifications. MnO and MnO2 doping have also shown significant improvements in the electromechanical performance of BNT-based ceramics [12,24]. For instance, introducing up to 1.5 mol% Mn into Bi0.5(Na0.88K0.08Li0.04)0.5(Ti1−xMnx)O3 compositions increased Qm from 402 to 974, albeit with a slight reduction in the piezoelectric coefficient (d33) and electromechanical coupling factor (kp) [43].

Innovative sintering techniques, such as flash sintering, have also been explored for BNT-based ceramics. Although this method reduces the grain size and consequently decreases Qm (from 980 to 650) compared to conventional sintering, it offers advantages in terms of processing efficiency and material densification [44].

Acceptor doping on both the A- and B-sites within the perovskite lattice has been explored to improve the performance. Notably, introducing bismuth deficiency in 0.88Bi0.50−xNa0.50TiO3-0.08Bi0.50−xK0.50TiO3-0.04BaTiO3 (BNKBT88) ceramics significantly enhances Qm. While stoichiometric BNKBT88 ceramics have a Qm of ~150, Bideficient ceramics achieve a remarkable Qm of ~1200 owing to oxygen vacancies and domain wall pinning caused by intrinsic defects [26].

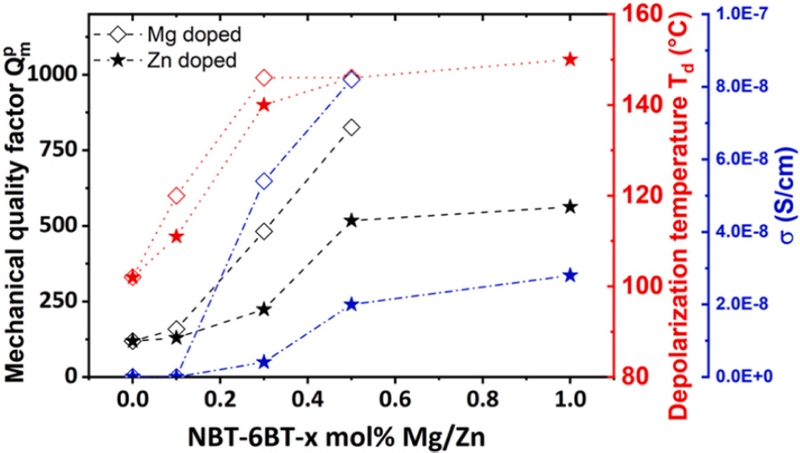

A recent study explored the effects of Mg doping on the 0.94Na1/2Bi1/2TiO3-0.06BaTiO3 (NBT-6BT) lead-free piezoceramic system, revealing significant improvements in the mechanical quality factor and depolarization temperature (Td) [15]. Mg doping increased the tetragonal phase fraction and non-cubic distortion, leading to a remarkable increase in Qm to 826 in NBT-6BT-0.5Mg, as shown in Fig. 2. This high Qm was stable under high vibration velocities, making the material suitable for high-power applications. However, piezoelectric coefficients decreased with increased doping, from 140 pC/N in undoped NBT-6BT to 112 pC/N in NBT-6BT-0.5Mg. These findings underscore the potential of Mg doping in enhancing the performance of NBT-BT ceramics for demanding applications while also highlighting the trade-offs in piezoelectric response.

Comparison of the mechanical quality factor Qm (black dashed), depolarization temperature Td (red dotted), and conductivity σ (blue dashed/dotted) at RT between Mg-doped (rectangular) and Zn-doped (star) NBT-6BT with different amounts of doping concentration. [15] Copyright (2022) Elsevier

Doping strategies and the introduction of secondary phases have been explored to enhance the performance of BNT-based ceramics. However, despite these efforts, BNT-based ceramics still face challenges in high-power applications owing to their relatively low piezoelectric coefficients (d33) and electromechanical coupling factors (kp). Addressing these limitations through advanced material design and processing techniques is essential to fully realize the potential of BNT-based ceramics for advanced high-power applications.

4. NKN-based High-power Piezoceramics

Potassium sodium niobate (Na0.5K0.5NbO3, NKN) is a mixed lead-free piezoelectric system that combines orthorhombic potassium niobate (KNbO3, KN) and sodium niobate (NaNbO3, NN). Initially identified as a ferroelectric material by Shirane in 1954 [45], NKN exhibits an orthorhombic phase (Amm2) at RT. On heating, the phase structure transitions from orthorhombic (Amm2) to tetragonal (P4mm) at approximately 200°C and further to a cubic phase (m3m) above its Curie temperature (TC) of approximately 420°C.

In 1959, Egerton and Dillon reported the piezoelectric and dielectric properties of pure NKN ceramics, which demonstrated a relatively low mechanical quality factor (Qm) of ~130 and a modest piezoelectric coefficient (d33) of ~80 pC/N [46]. Subsequent work by Du et al. showed that a relative density of 97.6% can be achieved using pressureless sintering, leading to improved properties with Qm~210 and d33~120 pC/N [47]. However, one of the key challenges in processing NKN-based ceramics is their poor sinterability, owing to the high volatility of alkaline elements at increased temperatures, making it difficult to achieve full densification and stoichiometric control.

To overcome these limitations, sintering aids have been widely used to enhance the sinterability and electromechanical performance of NKN ceramics. CuO, in particular, has proven effective in reducing sintering temperatures while improving Qm and other performance metrics. In Li/Ta-modified NKN systems, CuO acts as an acceptor dopant that enhances sintering behavior and significantly increases Qm [36]. Notably, Tan demonstrated that Cu2+-doped NKN ceramics can achieve a Qm as high as ~1241, whereas ultrahigh Qm values exceeding 2500 have also been reported for Cu-doped NKN ceramics [48]. Interestingly, CuO addition imparts some “soft” characteristics, likely owing to the substitution of Cu2+ for Li+, leading to a reduction in the coercive field (EC) and Curie temperature (TC).

In addition to CuO, codoping with other oxides has been explored as an effective strategy for enhancing the overall electromechanical performance of NKN ceramics [29,49,50], particularly for high-power applications. Small additions of compounds, such as K4CuNb8O23 (KCN) and K5.4Cu1.3Ta10O29 (KCT), also improve the sinterability without compromising the piezoelectric properties [51]. For example, Matsubara et al. reported an increase in Qm to 1200 when KCN was used as a sintering aid. Codoping with oxides in combination with KCN or KCT further enhances piezoelectric and dielectric properties, achieving significant improvements in Qm [34].

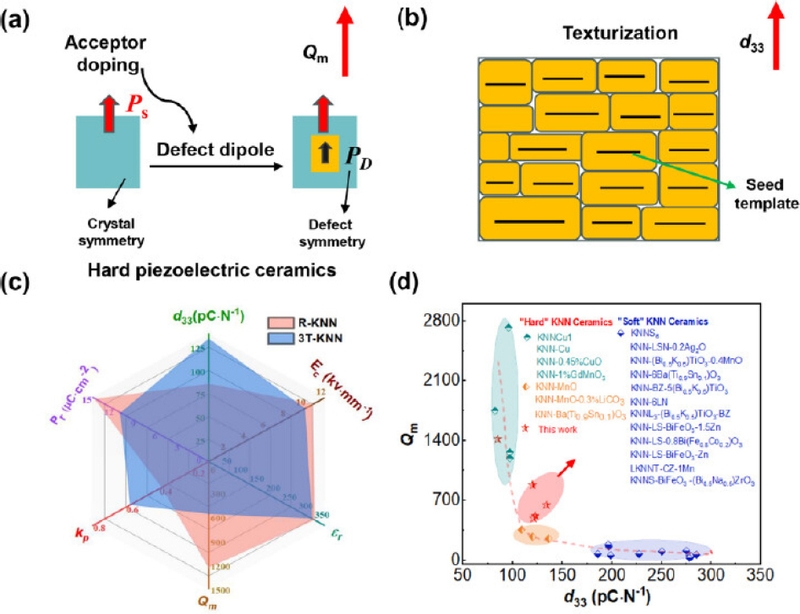

A recent study on textured NKN ceramics highlighted an innovative approach that combined acceptor doping and texturing techniques to achieve high mechanical quality factors and piezoelectric coefficients, as shown in Fig. 3. By incorporating CuO as a dopant and NaNbO3 templates for texturing, the researchers achieved exceptional properties, such as d33~134, Qm~582, kp = 0.58, and a Curie temperature (TC) of approximately 415°C. The texturing process enhanced grain orientation along the <001> direction, leading to improved piezoelectric performance while maintaining high mechanical robustness. This study demonstrates the potential of textured NKN ceramics as promising candidates for replacing leadbased piezoelectric materials in high-power applications. Further optimization of the processing conditions could enhance their performance for broader industrial use.

NKN piezoelectric ceramics. Acceptor doping made the piezoelectric ceramics “hardened” and the Qm value increased (a). The texture technique was used to improve d33 (b). A comparison of piezoelectric properties between R-NKN and 3T-NKN (c). The d33 and Qm for different NKN-based piezoceramics, and with high Qm and high d33 reported in paper (d). [17] Copyright (2024) American Chemical Society

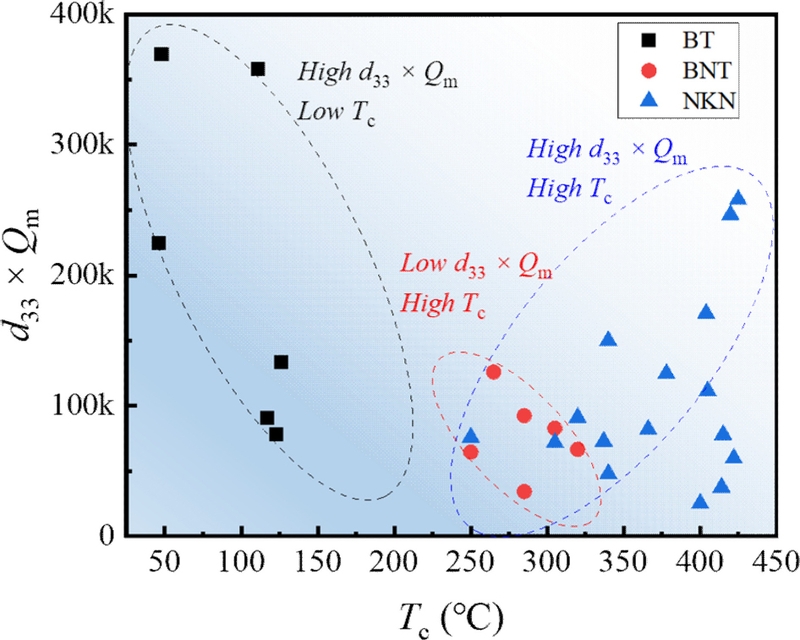

Although NKN-based ceramics exhibit substantial potential for high-power applications owing to their ultrahigh Qm and favorable electromechanical properties, challenges remain. The volatility and hygroscopic nature of alkaline elements, along with the relatively low dielectric constants and piezoelectric coefficients (d33), hinder their full utilization. Future research must focus on addressing these issues to further optimize NKN-based ceramics, particularly by improving their thermal and chemical stability while enhancing d33 and the dielectric constant (εr) without sacrificing their high Qm. The d33*Qm versus Curie temperature (TC) of BT-, BNT-, and NKN-based piezoelectric ceramics are summarized in Fig. 4.

5. CONCLUSIONS

Lead-free piezoelectric ceramics, including BT, BNT, and NKN, have emerged as strong candidates for replacing leadbased materials, such as PZT, in high-power applications. Each system offers unique advantages, but challenges remain in achieving optimized performance for practical use. BT-based ceramics demonstrate excellent piezoelectric properties but suffer from a low Curie temperature (TC). Enhancements through advanced sintering techniques and doping, such as Li2O additions, have improved their mechanical quality factor (Qm) and piezoelectric coefficients (d33). However, increasing their thermal stability remains essential for broader applicability. BNT-based ceramics benefit from a high TC (~320°C) and tunable electromechanical properties. Although doping strategies, such as Mn or Bi-deficiency, have significantly improved their Qm, these materials still exhibit relatively low d33 and electromechanical coupling factors, which limits their use in high-power applications. NKN-based ceramics offer remarkable potential, particularly owing to their ultrahigh Qm and high TC. The addition of sintering aids such as CuO and co-doping with various oxides has improved their sinterability and performance. Nonetheless, challenges related to the volatility and hygroscopic nature of alkaline elements must be addressed. Overall, lead-free piezoelectric ceramics show promising advancements but require further optimization to overcome their respective limitations. Continued research into doping, microstructural control, and sintering processes will be key to fully realizing their potential for high-power applications in the industrial and technological sectors.

Acknowledgments

The authors acknowledge this work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (RS-2024-00448865) and Korea Evaluation Institute of Industrial Technology (KEIT) grant funded by the Korea government (MOTI) (RS-2024-00419333).

References

-

W.W. Wolny, Application driven industrial development of piezoceramics, J. Eur. Ceram. Soc. 25 (2005) 1971–1976.

[https://doi.org/10.1016/j.jeurceramsoc.2005.03.221]

-

H.J. Lee, S. Zhang, Y. Bar-Cohen, S. Sherrit, High Temperature, High Power Piezoelectric Composite Transducers, Sensors 14 (2014) 14526–14552.

[https://doi.org/10.3390/s140814526]

-

S. Zhang, R. Xia, L. Lebrun, D. Anderson, T.R. Shrout, Piezoelectric materials for high power, high temperature applications, Mater. Lett. 59 (2005) 3471–3475.

[https://doi.org/10.1016/j.matlet.2005.06.016]

-

S. Wang, J. Shan, H. Tian, S. Lin, The High-Power Piezoelectric Transformer with Multiple Outputs Based on Sandwiched Piezoelectric Transducers, IEEE Trans. Power Electron. 37 (2022) 8886–8894.

[https://doi.org/10.1109/TPEL.2022.3157620]

-

W. Chen, S. Ma, X. Lai, Z. Wang, H. Zhao, Q. Zha, et al., Design, Fabrication, Characterization, and Simulation of AlN-Based Piezoelectric Micromachined Ultrasonic Transducer for Sonar Imaging Applications, Micromachines 15 (2024) 781.

[https://doi.org/10.3390/mi15060781]

-

D. Chen, L. Wang, X. Luo, C. Fei, D. Li, G. Shan, et al., Recent Development and Perspectives of Optimization Design Methods for Piezoelectric Ultrasonic Transducers, Micromachines 12 (2021) 779.

[https://doi.org/10.3390/mi12070779]

-

L. Chen, H. Liu, H. Qi, J. Chen, High-electromechanical performance for high-power piezoelectric applications: Fundamental, progress, and perspective, Prog. Mater. Sci. 127 (2022) 100944.

[https://doi.org/10.1016/j.pmatsci.2022.100944]

-

E. Cross, Lead-free at last, Nature 432 (2004) 24–25.

[https://doi.org/10.1038/nature03142]

-

M.-H. Zhang, K. Wang, Y.-J. Du, G. Dai, W. Sun, G. Li, et al., High and Temperature-Insensitive Piezoelectric Strain in Alkali Niobate Lead-free Perovskite, J. Am. Chem. Soc. 139 (2017) 3889–3895.

[https://doi.org/10.1021/jacs.7b00520]

-

H.-C. Thong, C. Zhao, Z. Zhou, C.-F. Wu, Y.-X. Liu, Z.-Z. Du, et al., Technology transfer of lead-free (K, Na) NbO3- based piezoelectric ceramics, Mater. Today 29 (2019) 37– 48.

[https://doi.org/10.1016/j.mattod.2019.04.016]

-

R. Ul, P. Marchet, M. Pham-Thi, L.-P. Tran-Huu-Hue, Improved Properties of Doped BaTiO3 Piezoelectric Ceramics, Phys. Status Solidi A 216 (2019) 1900413.

[https://doi.org/10.1002/pssa.201900413]

-

Q. Zhang, S. Jiang, T. Yang, Pyroelectric, dielectric, and piezoelectric properties of MnO2-doped (Na0.82K0.18)0.5Bi0.5TiO3 lead-free ceramics, J. Electroceram. 29 (2012) 8–11.

[https://doi.org/10.1007/s10832-012-9729-0]

-

T. Wang, D. Wang, Y. Liao, Q. Zheng, H. Sun, K. Kwok, et al., Defect structure, ferroelectricity and piezoelectricity in Fe/Mn/Cu-doped K0.5Na0.5NbO3 lead-free piezoelectric ceramics, J. Eur. Ceram. Soc. 38 (2018) 4915–4921.

[https://doi.org/10.1016/j.jeurceramsoc.2018.07.019]

-

G. Wang, Y. Yang, Z. Zhou, X. Ren, Y. Ji, High mechanical quality factor and high piezoelectric coefficient achieved via acceptor-modified invisible boundary, J. Eur. Ceram. Soc. 45 (2025) 117100.

[https://doi.org/10.1016/j.jeurceramsoc.2024.117100]

-

D. Bremecker, M. Slabki, J. Koruza, J. Rödel, Characterization of crystal structure, electrical and electromechanical properties of Mg-doped 0.94Na1/2Bi1/2TiO3-0.06BaTiO3, J. Eur. Ceram. Soc. 42 (2022) 5591–5597.

[https://doi.org/10.1016/j.jeurceramsoc.2022.06.032]

-

L. Zhao, B.-P. Zhang, P.-F. Zhou, L.-F. Zhu, J.-F. Li, Effect of Li2O addition on sintering and piezoelectric properties of (Ba,Ca) (Ti,Sn)O3 lead-free piezoceramics, J. Eur. Ceram. Soc. 35 (2015) 533–540.

[https://doi.org/10.1016/j.jeurceramsoc.2014.08.042]

-

D. Liu, L.-F. Zhu, T. Tang, J.-R. Li, L. Wang, Y.-X. Liu, J. Hao, S. Wang, K. Wang, Textured Potassium Sodium Niobate Lead-Free Ceramics with High d33 and Qm for Meeting High-Power Applications, ACS Appl. Mater. Interfaces 16 (2024) 7444–7452.

[https://doi.org/10.1021/acsami.3c16488]

-

H. Jaffe, Piezoelectric Ceramics, J. Am. Ceram. Soc. 41 (1958) 494–498.

[https://doi.org/10.1111/j.1151-2916.1958.tb12903.x]

-

W. Liu, X. Ren, Large Piezoelectric Effect in Pb-Free Ceramics, Phys. Rev. Lett. 103 (2009) 257602.

[https://doi.org/10.1103/PhysRevLett.103.257602]

-

H. Takahashi, Y. Numamoto, J. Tani, K. Matsuta, J. Qiu, S. Tsurekawa, Lead-Free Barium Titanate Ceramics with Large Piezoelectric Constant Fabricated by Microwave Sintering, Jpn. J. Appl. Phys. 45 (2005) L30.

[https://doi.org/10.1143/JJAP.45.L30]

-

H. Maiwa, Electromechanical Properties of BaTiO3 Ceramics Prepared by Spark Plasma Sintering and Other Methods, Jpn. J. Appl. Phys. 48 (2009) 09KD04.

[https://doi.org/10.1143/JJAP.48.09KD04]

-

D. Tanaka, J. Yamazaki, M. Furukawa, T. Tsukada, High Power Characteristics of (Ca,Ba)TiO3 Piezoelectric Ceramics with High Mechanical Quality Factor, Jpn. J. Appl. Phys. 49 (2010) 09MD03.

[https://doi.org/10.1143/JJAP.49.09MD03]

-

C.-C. Tsai, W.-H. Chao, S.-Y. Chu, C.-S. Hong, C.-M. Weng, H.-H. Su, Enhanced temperature stability and quality factor with Hf substitution for Sn and MnO2 doping of (Ba0.97Ca0.03)(Ti0.96Sn0.04)O3 lead-free piezoelectric ceramics with high Curie temperature, AIP Adv. 6 (2016) 125024.

[https://doi.org/10.1063/1.4972201]

-

M. Zhu, H. Hu, N. Lei, Y. Hou, H. Yan, MnO Modification on Microstructure and Electrical Properties of Lead-Free Bi0.485Na0.425K0.06Ba0.03TiO3 Solid Solution Around Morphotropic Phase Boundary, Int. J. Appl. Ceram. Technol. 7 (2010) E107–E113.

[https://doi.org/10.1111/j.1744-7402.2009.02444.x]

-

M. Hejazi, E. Taghaddos, E. Gurdal, K. Uchino, A. Safari, High Power Performance of Manganese-Doped BNT - Based Pb-Free Piezoelectric Ceramics, J. Am. Ceram. Soc. 97 (2014) 3192–3196.

[https://doi.org/10.1111/jace.13098]

-

G. Yesner, A. Safari, Improved resistivity in bismuth deficient morphotropic phase boundary 0.88BNT-0.08BKT- 0.04BT ceramics, Proceedings of 2017 Jt. IEEE Int. Symp. Appl. Ferroelectr. (ISAF) / International Workshop Acoust. Transduct. Mater. Devices (IWATMD) / Piezoresponse Force Microsc. (PFM), Atlanta, USA, 2017, pp. 110–112.

[https://doi.org/10.1109/ISAF.2017.8000224]

-

Y. Liao, D. Wang, H. Wang, T. Wang, X. Wei, Q. Zheng, et al., Defect-induced transformation between hardening and softening behaviors in CuF2-doped K0.5Na0.5NbO3 piezoceramics, Ceram. Int. 45 (2019) 2644–2652.

[https://doi.org/10.1016/j.ceramint.2018.10.211]

-

Y. Liao, D. Wang, H. Wang, L. Zhou, Q. Zheng, D. Lin, Modulation of defects and electrical behaviors of Cu-doped KNN ceramics by fluorine–oxygen substitution, Dalton Trans. 49 (2020) 1311–1318.

[https://doi.org/10.1039/C9DT04133H]

-

S. Su, R. Zuo, X. Wang, L. Li, Sintering, microstructure and piezoelectric properties of CuO and SnO2 co-modified sodium potassium niobate ceramics, Mater. Res. Bull. 45 (2010) 124–128.

[https://doi.org/10.1016/j.materresbull.2009.09.033]

-

R. Zuo, B. Ma, Y. Liu, Z. Xu, Hardening characteristics and compositional dependence of piezoelectric properties in Cu2+ modified 0.52NaNbO3–(0.48−x) KNbO3–xLiNbO3 ceramics, J. Alloys Compd. 488 (2009) 465–468.

[https://doi.org/10.1016/j.jallcom.2009.09.012]

-

Y. Zhao, Y. Zhao, R. Huang, R. Liu, H. Zhou, Effect of Sintering Temperature on Microstructure and Electric Properties of 0.95(K0.5Na0.5) NbO3–0.05Li (Nb0.5Sb0.5) O3 with Copper Oxide Sintering Aid, J. Am. Ceram. Soc. 94 (2011) 656–659.

[https://doi.org/10.1111/j.1551-2916.2010.04353.x]

-

M.-K. Choi, H.-Y. Park, I.-T. Seo, J.-H. Choi, W. Kim, S. Nahm, et al., Effect of Li2O and CuO additives on the structural and piezoelectric properties of (Na0.5K0.5) (Nb0.96Sb0.04) O3 lead-free piezoelectric ceramics, Curr. Appl. Phys. 11 (2011) 598–603.

[https://doi.org/10.1016/j.cap.2010.10.005]

-

D. Lin, M. Guo, K. H. Lam, K. W. Kwok, H. Chan, Leadfree piezoelectric ceramic (K0.5Na0.5) NbO3 with MnO2 and K5.4Cu1.3Ta10O29 doping for piezoelectric transformer application, Smart Mater. Struct. 17 (2008) 035002.

[https://doi.org/10.1088/0964-1726/17/3/035002]

-

B.C. Park, I.K. Hong, H.D. Jang, V.D.N. Tran, W.P. Tai, J.- S. Lee, Highly enhanced mechanical quality factor in leadfree (K0.5Na0.5) NbO3 piezoelectric ceramics by co-doping with K5.4Cu1.3Ta10O29 and CuO, Mater. Lett. 64 (2010) 1577–1579.

[https://doi.org/10.1016/j.matlet.2010.04.031]

-

Y. Lv, C. Wang, J. Zhang, M. Zhao, M. Li, H. Wang, Modified (K0.5Na0.5) (Nb0.9Ta0.1) O3 ceramics with high Qm, Mater. Lett. 62 (2008) 3425–3427.

[https://doi.org/10.1016/j.matlet.2008.02.079]

-

Z.-Y. Shen, Y. Xu, J.-F. Li, Enhancement of Qm in CuOdoped compositionally optimized Li/Ta-modified (Na,K) NbO3 lead-free piezoceramics, Ceram. Int. 38 (2012) S331–S334.

[https://doi.org/10.1016/j.ceramint.2011.04.113]

-

Y. Hirose, K. Maruyama, T. Kimura, K. Kitamura, H. Yamada, T. Kurahashi, et al., Fabrication of (K,Na) NbO3- based composite lead-free piezoelectric ceramics and their high-power properties, J. Ceram. Soc. Jpn. 131 (2023) 248– 251.

[https://doi.org/10.2109/jcersj2.22164]

-

Y. Xie, J. Xing, Z. Tan, L. Xie, Y. Cheng, X. Wu, et al., High mechanical quality factor and piezoelectricity in potassium sodium niobate ceramics, Ceram. Int. 48 (2022) 6565–6573.

[https://doi.org/10.1016/j.ceramint.2021.11.204]

- G.A. Smolensky, V.A. Isupov, A.I. Agranovskaya, N.N. Krainic, New ferroelectrics with complex compounds. IV, Fiz. Tverd. Tela 2 (1960) 2982–2985.

-

T. Takenaka, K.O. Sakata, K.O. Toda, Piezoelectric properties of (Bi1/2Na1/2) TiO3-based ceramics, Ferroelectrics 106 (1990) 375–380.

[https://doi.org/10.1080/00150199008214612]

-

S. Someno, H. Nagata, T. Takenaka, High-temperature and high-power piezoelectric characteristics of (Bi0.5Na0.5) TiO3-Based lead-free piezoelectric ceramics, J. Ceram. Soc. Jpn. 122 (2014) 406–409.

[https://doi.org/10.2109/jcersj2.122.406]

-

W. Lu, G. Fan, X. Wang, F. Liang, Dielectric and Piezoelectric Properties of [Bi0.5(Na1-xLix)0.5]TiO3 Lead- Free Ceramics, Jpn. J. Appl. Phys. 45 (2006) 8763.

[https://doi.org/10.1143/JJAP.45.8763]

-

M. Hejazi, E. Taghaddos, E. Gurdal, K. Uchino, A. Safari, High Power Performance of Manganese-Doped BNT-Based Pb-Free Piezoelectric Ceramics, J. Am. Ceram. Soc. 97 (2014) 3192–3196.

[https://doi.org/10.1111/jace.13098]

-

E. Taghaddos, H. Charalambous, T. Tsakalakos, A. Safari, Electromechanical properties of flash sintered BNT-based piezoelectric ceramic, J. Eur. Ceram. Soc. 39 (2019) 2882– 2888.

[https://doi.org/10.1016/j.jeurceramsoc.2019.03.050]

-

G. Shirane, R. Newnham, R. Pepinsky, Dielectric Properties and Phase Transitions of NaNbO3 and (Na,K) NbO3, Phys. Rev. 96 (1954) 581.

[https://doi.org/10.1103/PhysRev.96.581]

-

L. Egerton, D.M. Dillon, Piezoelectric and Dielectric Properties of Ceramics in the System Potassium—Sodium Niobate, J. Am. Ceram. Soc. 42 (1959) 438–442.

[https://doi.org/10.1111/j.1151-2916.1959.tb12971.x]

-

H. Du, Z. Li, F. Tang, S. Qu, Z. Pei, W. Zhou, Preparation and piezoelectric properties of (K0.5Na0.5) NbO3 lead-free piezoelectric ceramics with pressure-less sintering, Mater. Sci. Eng. B 131 (2006) 83–87.

[https://doi.org/10.1016/j.mseb.2006.03.039]

-

X. Tan, H. Fan, S. Ke, L. Zhou, Y.-W. Mai, H. Huang, Structural dependence of piezoelectric, dielectric and ferroelectric properties of K0.5Na0.5(Nb1−2x/5Cux) O3 leadfree ceramics with high Qm, Mater. Res. Bull. 47 (2012) 4472–4477.

[https://doi.org/10.1016/j.materresbull.2012.09.049]

-

D. Lin, K. W. Kwok, H. Chan, Piezoelectric and ferroelectric properties of KxNa1−xNbO3 lead-free ceramics with MnO2 and CuO doping, J. Alloys Compd. 461 (2008) 273–278.

[https://doi.org/10.1016/j.jallcom.2007.06.128]

-

W. Wu, M. Chen, J. Li, Y. Ding, C. Liu, Structure and asymmetric ferroelectric loops of (K0.48Na0.52) NbO3– 1mol%CuO–xmol%Co2O3 ceramics with low-temperature sintering, J. Alloys Compd. 670 (2016) 128–134.

[https://doi.org/10.1016/j.jallcom.2016.02.001]

-

M. Matsubara, T. Yamaguchi, K. Kikuta, S.-i. Hirano, Sinterability and Piezoelectric Properties of (K,Na) NbO3 Ceramics with Novel Sintering Aid, Jpn. J. Appl. Phys. 43 (2004) 7159.

[https://doi.org/10.1143/JJAP.43.7159]

Dr. Dong-Gyu Lee is a postdoctoral researcher in the Department of Materials Science and Engineering at Korea University. He received his Ph.D. from Korea University in 2024, where he studied piezoelectric ceramics and energy harvesting technologies. Prior to his postdoctoral appointment, he worked as a commissioned researcher at the Korea Institute of Science and Technology (KIST), focusing on high-power piezoelectric transducers and lead-free piezoelectric materials. His research interests include functional ceramics, ferroelectric materials, and energy conversion devices, and he has published in leading journals in these fields.

Prof. Hyun-Cheol Song is an Associate Professor in the Department of Materials Science and Engineering at Korea University, a position he has held since 2025. Prior to joining Korea University, he worked as a Principal Research Scientist at the Korea Institute of Science and Technology (KIST) from 2006. He received his B.S. and M.S. degrees in Materials Science and Engineering from Korea University in 2004 and 2006, respectively, and earned his Ph.D. in the same field from Virginia Tech in 2017. His research focuses on energy conversion materials and devices for sensor and actuator applications. In particular, he is interested in developing novel power generation mechanisms based on high-performance piezoelectric and triboelectric materials. His recent work explores acoustic wireless energy transfer technologies for bio-implantable devices and underwater unmanned drones. He has authored over 100 peer-reviewed publications and holds more than 40 patents in the fields of advanced materials and device technologies.