Engineered Stretchability of Conformal Parylene Thin-film On-skin Electronics

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License(https://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Skin-compatible electronics have evolved to achieve both conformality and stretchability for stable contact with deformable biological skin. While existing research has largely concentrated on alternative materials, the potential of Parylene-based thin-film electrodes for stretchable on-skin applications remains relatively untapped. This study proposes an engineering strategy to achieve stretchability using the Parylene thin-film electrode. Unlike the conventional Parylene thin-film electrode, we introduce morphological adaptability via controlled microscale slits in the Parylene electrode structure. The slits-containing device enables unprecedented stretchability while maintaining critical electrical insulation properties during mechanical deformation. Finally, the demonstration on human skin shows the mechanical adaptability of these Parylene-based bioelectrodes while their electrical characteristics remain stable during various stretching conditions. Owing to the ultra-thinness of the Parylene coating, the wearable bioelectrode not only achieves stretchability but also conforms to the skin. Our findings broaden the practical use of Parylene thin-film bioelectrodes.

Keywords:

Stretchable bioelectrodes, Parylene thin-film, Conformal adhesion, Morphological adaptability1. INTRODUCTION

The field of wearable and on-skin electronics has witnessed remarkable progress in recent years, enabling a wide range of applications in healthcare monitoring, diagnostics, and human-machine interfaces [1]. Among these developments, thin-film bioelectrodes have garnered significant attention owing to their potential for noninvasive and continuous monitoring of physiological signals. When seamlessly integrated onto the skin, these electrodes have the capability to gather real-time information, revolutionizing the way we interact with and understand the human body [2].

However, one of the key challenges in the design of on-skin bioelectrodes lies in striking a balance between mechanical flexibility and reliable electrical performance [3]. Although amorphous materials such as polydimethylsiloxane and ECO flex have been employed to create intrinsically stretchable electrodes, they often exhibit limitations in terms of their electrical and ionic insulation capabilities [4]. These shortcomings compromise on the accuracy and longevity of signal acquisition, especially when used in the ionic biological environment. Consequently, the pursuit of a material that combines both mechanical resilience and superior electrical properties is an ongoing endeavor.

Here, this research presents a novel approach toward addressing the challenge of achieving stretchability and conformal adhesion in thin-film bioelectrodes. Unlike conventional methods that rely on inherently stretchable amorphous materials, we focus on enhancing the mechanical properties of a semi-crystalline material, specifically Parylene-based electrodes, through facile engineering techniques. Parylene, recognized for its excellent electrical insulation via chemical vapor deposition that seamlessly coats the entire surface of the target, serves as the foundational material for our study.

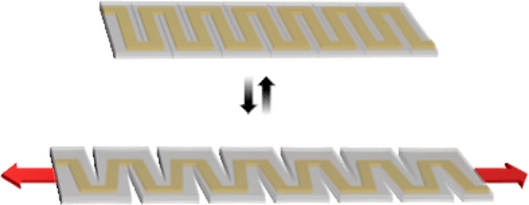

Engineering stretchability by introducing controlled microscale slits within the Parylene-based thin-film devices is proposed (Fig. 1). These strategically designed slits unlock a new dimension of morphological adaptability, allowing the devices to maintain their electrical and ionic insulation properties even during stretching. We demonstrate the feasibility of this engineering approach through systematic experimentation, highlighting the potential for Parylene thin-film bioelectrodes to achieve both stretchability and conformal adhesion without compromising on performance.

The detailed fabrication procedure of the Parylene-based thin-film bioelectrodes and that of the controlled slits in their structure is described. A comprehensive analysis of the stretchable characteristics achieved by varying the density of the slits provides insights into the attainable degree of mechanical adaptability. The results also delve into the electrical characteristics of the devices under stretching conditions, highlighting their impedance stability. Finally, we demonstrate the application of these novel stretchable electrodes on human skin, representing their potential for real-world application.

By merging the structural stretchability with the intrinsic dielectric properties of Parylene, our research presents a promising guideline for enhancing the capabilities of on-skin bioelectrodes. The results presented herein not only underscore the feasibility of our approach but also open doors to a new era of wearable electronics that seamlessly integrate with the dynamic nature of the human movement.

2. EXPERIMENTAL

2.1 Preparation and characterization of stretchable Parylene thin-film electrode

Parylene-C was purchased from Specialty Coating Systems, Singapore. Ethanol was purchased from Sigma-Aldrich. All water used was prepared by Millipore. Parylene-C was evaporated via the PDS 2010 Labcoater 2 vacuum deposition system, Specialty Coating Systems, Singapore. Metal was evaporated using a thermal metal evaporator, One Science, Republic of Korea.

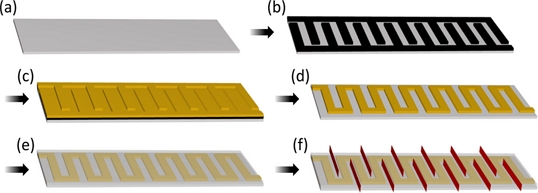

The glass substrate is cleaned with ethanol before use. A 400 nm thick first layer of Parylene substrate is pre-deposited onto the glass substrate (Fig. 2(a)). The glass substrate is then laminated with a shadow mask containing micro-scale patterns (Width: 1 mm), which is made using a paper cutter (Silhouette, Korea, Republic of) (Fig. 2(b)). Gold is evaporated using a thermal metal evaporator to a thickness of 100 nm (Fig. 2(c)). The shadow mask is carefully removed from the metal-deposited glass substrate (Fig. 2(d)). A second layer of Parylene coating is applied with a thickness of 400 nm (Fig. 2(e)). The resultant thin-film electrodes are cut using a blade to form slits within their structure (Fig. 2(f)). Finally, the thin-film Parylene-metal-Parylene sandwich layers are carefully peeled off from the glass substrate and then transferred to human skin tissue.

Because the prepared ultra-thin electronic device is prone to deformation during the transfer procedure, the skin is pre-treated with ethanol to prevent both electrostatic interactions within the thin-film device and between the device and skin tissue.

The LCR meter was used to measure the impedance of the thin-film electrode at a frequency of 1 kHz. Both end parts of the serpentine-shaped micro-scale metal thin-film patterns are connected to copper-nickel wires for ease of measurement.

3. RESULTS AND DISCUSSIONS

3.1 Morphological characterization of stretchable thin-film electrode

Thin-film parylene electrodes were analyzed in a controlled strain-applied environment. The mechanical adaptability of both conventional thin-film electrodes and the slit-containing stretchable thin-film electrodes was demonstrated on the human skin and compared. The deformation of the skin and the subsequent stress applied to the thin-film device were analyzed through a comprehensive understanding of the mechanical structure of the slits within the device.

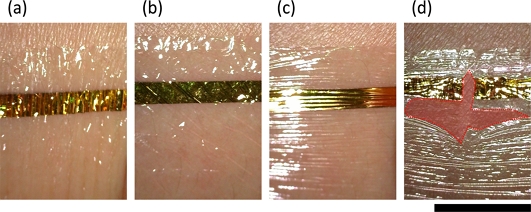

Controlled physical deformation was applied to the conventional thin-film device attached to human skin. Fig. 3 shows the device in its compressed state (Fig. 3(a)), released state (Fig. 3(b)), stretched state (Fig. 3(c)), and finally, the device is shown as ruptured owing to the extreme strain applied (20% stretching).

Deformation of thin-film electrode under different strains; Strain: (a) -20%, (b) 0%, (c) 10%, and (d) 20%. The Red-colored area indicates the breakage of the metal electrode. (Scale bar: 8 mm).

The conformal contact of the thin-film device exhibited a high restoring capability even under the compressive force (-20% strain), despite the formation of numerous wrinkles that could potentially hinder the stable attachment of conventional bulky wearable devices to soft skin tissue.

The characteristic of the shape retention was partially observed under positive strain (10% strain). The plastic deformation, accompanied by the formation of tiny opaque wrinkles all over the surface of the device, appeared to be monitored in the thin film device, because the ultra-thin structure is known to enable even rigid materials to be stretchable at a microscopic level.

However, at a higher strain (20%), the thin-film device ruptured. The breakage of the device initiated from the gold-deposited center as the mechanical stress became concentrated at the interface between the metal and polymer surfaces, which is visualized as the red color in Fig. 3(d).

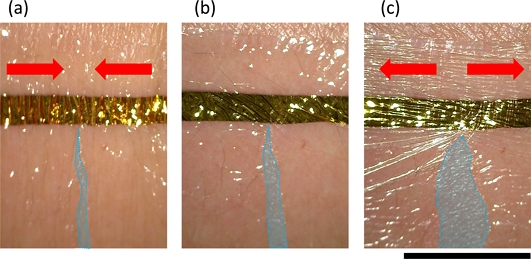

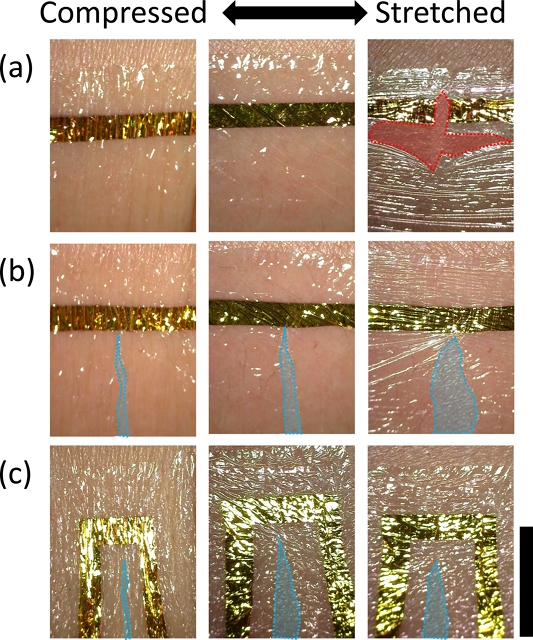

Controlled physical deformation was applied to the slit-containing thin-film device attached to the human skin. Fig. 4 represents the device in its compressed state (Fig. 4(a)), released state (Fig. 4(b)), and stretched state (Fig. 4(c)).

Deformation of thin-film electrode with the slit under different strains; Strain: (a) -20%, (b) 0%, and (c) 20%. The blue-colored area represents the size of the slits. (Scale bar: 8 mm).

The pre-formed slit within the thin-film device has the ability to shrink its area under compressive force and expand it under tension. Unlike the conventional parylene-based thin-film structure, which barely allows elastic recovery when stretched, the engineered physical slit acts as a stress-releasing joint by modulating its area in response to the deformation of the skin tissue.

It is noteworthy that the change in the size of the slit during skin deformation does not result in noticeable detachment or unwanted movement of the thin-film device on the skin tissue, owing to its conformal contact that enables stable adhesion. Both the conformal contact of the thin-film structure and stress-releasing feature of the slit contribute to the mechanical adaptability of the device.

3.2 Optimized mechanical adaptability and electrical characterization

While the thin-film structure allows the device to deform without undergoing plastic deformation, there is a possibility that the electrical properties may be affected during deformation. We conducted experiments to evaluate the relationship between the strain and electrical characteristics.

We demonstrated the controlled density of slits within the device on a thin-film device with micro-patterned metal, as shown in Fig. 1(f).

Fig. 5 illustrates the behavior of the slits formed within the thin-film device based on the number of slits in the unit area (24 mm × 32 mm): no slits per unit area (Fig. 5(a)), four slits per unit area (Fig. 5(b)), and eight slits per unit area (Fig. 5(c)). All devices were exposed to compression and tension while firmly attached to human skin.

Deformation of thin-film electrode with different numbers of slit. Amount of slit: (a) 0, (b) 4, and (c) 8. The Red colored area indicates the breakage of the metal electrode, whereas the blue-colored area represents the size of the slits. (Scale bar: 8mm).

As each slit contributes to the release of stress, under the same tension (20%), a higher density of slits exhibited less change in the size of each slit. This implies that a higher density of slits may provide greater stability for the Parylene thin-film device. However, it is also noteworthy that human skin is usually stretched only to some extent, which suggests that there could be an ideally required density of slits based on their application.

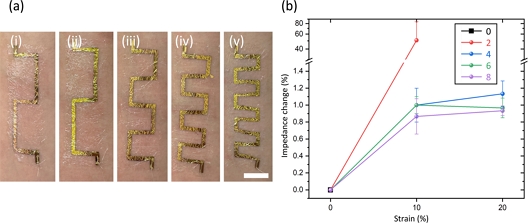

Finally, electrical characterization was performed, because the primary purpose of the device is its application as a reliable and deformable circuit. The density of the slits was controlled to quantitatively understand the optimal structure of the slit-based stretchable parylene thin-film device (Fig. 6(a)).

Impedance changes of thin-film electrodes with different numbers of slits. (a) Number of slits: (i) 0, (ii) 2, (iii) 4, (iv) 6, and (v), and (b) impedance change of the electrodes with different numbers of slits by varying strain applied to the skin tissue. All experiments are repeated three times. (Scale bar: 2 cm).

Fig. 6 shows the impedance change during the controlled deformation of the devices. The conventional thin-film parylene device with no slits showed no capacity to endure the strain, even with a 10% change, resulting in an immediate circuit open. The device with two slits showed a relatively significant impedance change (higher than 50%) but still maintained its conductivity under a 10% strain. When the number of slits exceeded 4, all devices exhibited no noticeable impedance change (less than 0.5%) from a 10% strain to a 20% strain.

4. CONCLUSIONS

In this study, we presented a straightforward and practical approach to address the challenge of achieving stretchability and conformal adhesion in parylene-based thin-film on-skin bioelectrodes. By introducing controlled microscale slits within the electrode structure, we successfully engineered a morphologically adaptive architecture that maintains its electrical insulation properties during stretching. Through systematic experimentation, we demonstrated the efficacy of this engineering strategy, highlighting the mechanical adaptability of the devices and their stable electrical performance under varying stretching conditions.

The significance of our findings lies not only in the advancement of stretchable electronics but also in the unprecedented integration of parylene-based thin-film bioelectrodes into the realm of wearable technology. The engineered stretchability achieved in this study defies conventional expectations, establishing a unique bridge between the material's inherent properties and practical engineering concepts. The successful application of these advanced bioelectrodes onto human skin further underscores their real-world feasibility, opening the possibility of a plethora of applications in healthcare, sports science, and beyond.

The results contribute to the expanding application of wearable electronics, shedding light on the potential of parylene as a formidable candidate for achieving both mechanical flexibility and electrical performance. As we transition towards a future marked by seamless human-machine interaction, the engineered stretchability of parylene thin-film on-skin bioelectrodes sets a new platform. We anticipate that our work will inspire further exploration and innovation, promoting the development of advanced wearable electronics that harmonize with the flexible and deformable human skin.

In conclusion, this research stands as a testament to the power of interdisciplinary collaboration, which encompasses material selection and engineering strategy. As we envision a future where wearable electronics seamlessly adapt to human motion, the engineered stretchability of the parylene thin-film bioelectrodes emerges as a chemically stable yet mechanically adaptive platform.

Acknowledgments

J. Lee conceived the idea and designed the experiments. J. Lee, G. Yun, J. Jeon, and P.T.L performed the experiment and analyzed the data. J. Lee, G. Yun, J. Jeon, P.T.L, T.S.H, S.W.K, and G. Lim wrote the manuscript. G. Lim supervised this project. This work was financially supported by the National R&D Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (2020M3H4A1A02084830), and the NRF grant funded by the Korean government (MSIT; No. NRF-2020R1I1A3074228).

REFERENCES

-

T. Someya and M. Amagai, “Toward a new generation of smart skins”, Nat. Biotechnol., Vol. 37, No. 4, pp. 382-388, 2019.

[https://doi.org/10.1038/s41587-019-0079-1]

-

T. Someya, Z. Bao, and G. G. Malliaras, “The rise of plastic bioelectronics”, Nature, Vol. 540, No. 7633, pp. 379-385, 2016.

[https://doi.org/10.1038/nature21004]

-

J. A Rogers, T. Someya, and Y. Huang, “Materials and mechanics for stretchable electronics”, Science, Vol. 327, No. 5973, pp. 1603-1607, 2010.

[https://doi.org/10.1126/science.1182383]

-

S. Nie, M. Cai, H. Yang, L. Shen, S. Wang, Y. Zhu, and J. Song, “Soft, stretchable thermal protective substrates for wearable electronics”, Npj Flex. Electron., Vol. 6, No. 1, pp. 36, 2022.

[https://doi.org/10.1038/s41528-022-00174-8]